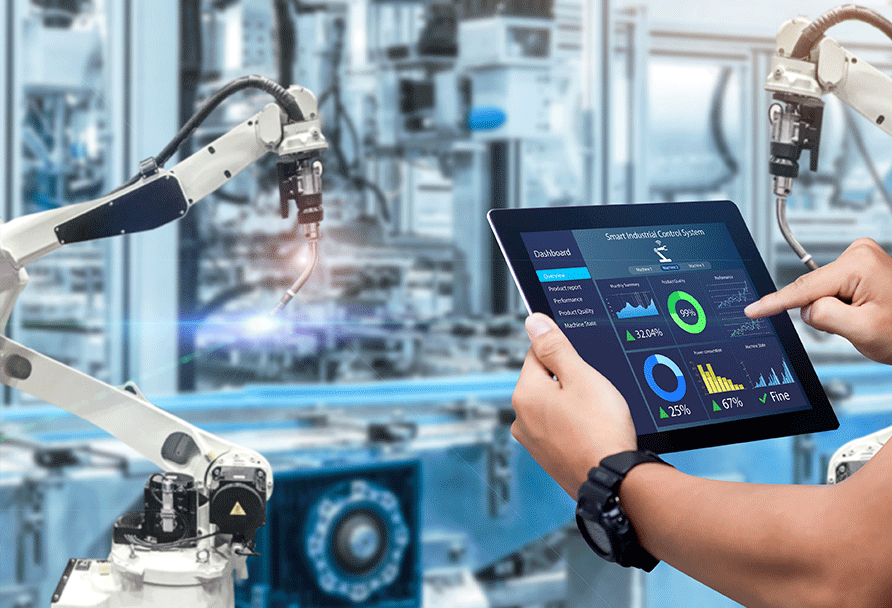

The Industrial Internet of Things (IIoT), as a combination of information technology and manufacturing, is gradually changing the face of traditional manufacturing. By connecting sensors, devices and networks, IIoT has a wide range of applications in manufacturing. Here are 8 main uses of the Industrial Internet of Things in manufacturing.

1.Asset Management

Monitor and track the usage of manufacturing equipment, machines and tools through IoT sensors to achieve real-time monitoring and management of assets. In this way, manufacturing companies can better understand the utilization and operating status of equipment, thereby optimizing equipment use and maintenance plans and improving production efficiency.

2. Production line optimization

IoT sensors can collect data about various aspects of the production line, such as temperature, pressure, speed and other information. These data can be used to monitor and optimize the performance of the production line to achieve real-time monitoring and adjustment of the production process, thereby improving production efficiency and product quality.

3. Predictive maintenance

By monitoring the health of equipment and machines, IoT enables predictive maintenance. Data collected by sensors can be used to analyze the health of equipment and signs of potential failures, detecting and fixing problems early to avoid production interruptions and increased repair costs.

4.Quality control

IoT sensors can monitor key parameters in the production process in real time and compare them with standards. In this way, manufacturing companies can detect product quality problems in a timely manner, take corrective measures, avoid the production of defective products, and improve product quality and customer satisfaction.

5. Logistics and supply chain management

IoT can track materials and goods in logistics and supply chains, enabling real-time monitoring and visualization. This helps increase logistics efficiency, reduce inventory and transportation costs, and improve supply chain reliability and traceability. Manufacturing companies can better understand the flow of materials and goods, make production and supply plans in advance, and improve overall operational efficiency.

6. Worker safety and health

IoT sensors can monitor factors such as temperature, humidity, gas concentration, etc. in the work environment and provide real-time alerts and notifications. This helps ensure the safety and health of workers and takes the necessary steps to prevent accidents and occupational diseases.

7. Energy saving and environmental monitoring

IoT can monitor and optimize energy usage, improve energy efficiency, and reduce energy costs. In addition, IoT sensors can also monitor environmental factors such as air quality, noise and vibration to ensure compliance with environmental standards and reduce environmental impact.

8. Data analysis and decision support

The vast amounts of data collected through IoT can be deeply analyzed and mined to gain insights into aspects such as manufacturing processes, equipment performance, and product quality. This data can be used to make decisions and optimize production processes, improving business performance and competitiveness.

Summarize

In general, the Industrial Internet of Things has many important uses in the manufacturing industry, and is gradually becoming an important tool and driving force for the transformation and upgrading of the manufacturing industry. With the continuous development and innovation of technology, the application prospects of IIoT in manufacturing will become broader. Manufacturing companies should actively explore and apply IIoT to improve efficiency, optimize quality, and lay a solid foundation for sustainable development.