With the in-depth promotion of Industry 4.0 and intelligent manufacturing, industrial control system, as a key link connecting the management layer and the execution layer, has become an important symbol to measure the degree of modernisation of enterprises with its intelligent and networked level. Industrial control gateway, as an ‘intelligent bridge’ to realise the information interaction between internal and external information of industrial control system, plays an irreplaceable role in enhancing the connectivity, security and intelligence level of industrial control network.

Industrial control gateway usually has many functions such as protocol conversion, data acquisition, remote management and security protection. In practical applications, it can connect industrial equipment with different communication protocols to achieve unified data collection and standardised processing; at the same time, through the built-in security mechanism, it can effectively isolate the industrial control network from the external network to prevent malicious attacks and illegal access.

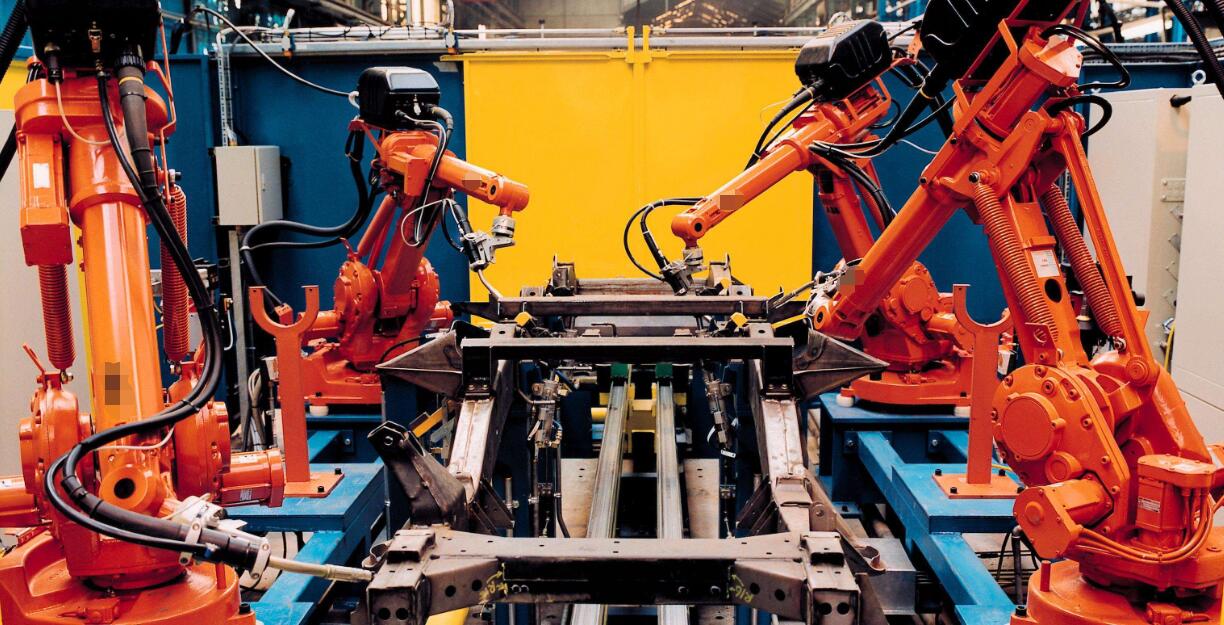

Taking the intelligent manufacturing production line as an example, the industrial control gateway has a wide range of application scenarios. In the production line, a variety of sensors, actuators, PLCs (programmable logic controllers) and other industrial control devices need to work together through real-time, accurate data interaction. However, these devices often use different manufacturers’ communication protocols and data formats, bringing great challenges to system integration and information interaction. At this point, the role of industrial control gateway comes to the fore.

After deploying industrial control gateway in the production line, it can firstly identify and access devices with various communication protocols, and through the built-in protocol conversion function, convert data of different protocols into a unified standard format, such as OPC UA, MQTT, etc., which is convenient for the upper management system to process and analyse the data. Secondly, industrial control gateway can collect real-time information on the operation status of equipment and production data on the production line and transmit them to the cloud or local server through high-speed and stable network to achieve visual monitoring and remote management of the production process.

In addition, the industrial control gateway also has strong security protection capability. It can effectively prevent external network attacks and virus invasion by means of whitelisting, firewall, intrusion detection, etc. to protect the safe and stable operation of production line control system. At the same time, the industrial control gateway also supports remote troubleshooting and firmware upgrade and other functions, which greatly improves the maintainability and expandability of the system.

In summary, the application of industrial control gateway in the field of intelligent manufacturing not only improves the automation level and production efficiency of the production line, but also enhances the security and manageability of the system. With the continuous development of Internet of Things technology and the continuous improvement of industrial control gateway function, I believe it will play a more important role in the future industrial control field.