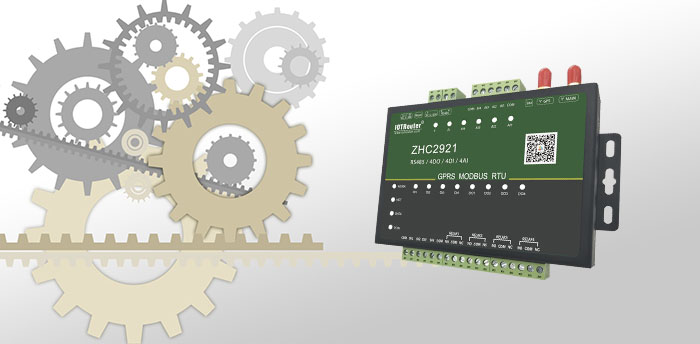

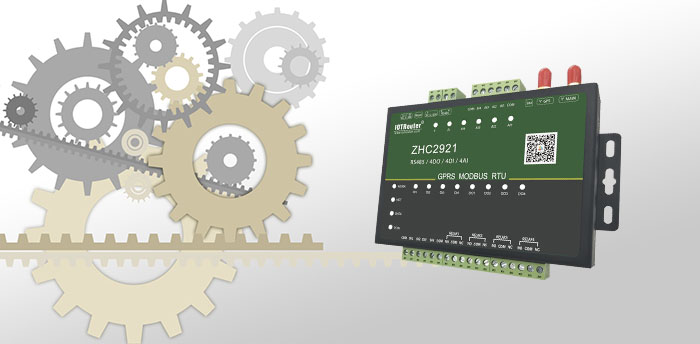

RTU is the abbreviation of Remote Terminal Unit (remote measurement and control terminal) and is the basic component unit of the SCADA system. Industrial RTU is an electronic device installed at a remote site. It is used to monitor, measure and collect sensors and equipment installed at the remote site. It is responsible for monitoring and controlling on-site signals and industrial equipment. Industrial RTU converts the measured status or signal into a data format that can be sent on the communication media. It also converts the data sent from the central computer into commands to realize functional control of the equipment.

Eine industrial RTU can have several, dozens or hundreds of I/O points, which can be placed in the field near the measurement point. Industrial RTU should have at least the following two functions: data collection and processing, data transmission (network communication). Of course, many RTUs also have PID control functions or logic control functions, flow accumulation functions, etc.

As a product that embodies the idea of ”decentralized measurement and control, centralized management” , industrial RTU was introduced to China in the 1980s and quickly became widely used. Its advantages in improving signal transmission reliability, reducing the burden on the host, reducing the amount of signal cables, and saving installation costs are also recognized by users.

Industrial RTU has a wide range of applications. It does not require wiring, reduces operation and maintenance costs, is easy to install, and is plug-and-play. It is suitable for water supply pipe networks, gas supply pipe networks, oil supply pipe networks, environment, manufacturing, chemical industry, energy, warehousing, Real-time collection, wireless transmission, on-site or remote monitoring and early warning of temperature in offices and other environments.

In addition to being widely used in traditional industrial production processes (such as power plants, steel plants, chemical plants), industrial RTU is widely used in situations where measurement and control points are particularly dispersed, such as in the following industries: urban water supply automation control systems; urban water supply automation control systems; Wastewater treatment system; city gas pipeline network comprehensive dispatching system; natural gas and petroleum industry automation system; electric power remote data centralized control system; heating network pipeline automation control; environmental monitoring of atmosphere/water quality; water regime and hydrology forecasting and reporting system; lighthouse beacon, river Shipping, port, and mine dispatching systems.