Smart factories are an important development direction in today’s industrial production field. They are based on Internet of Things technology and realize the automation and optimization of production processes through connections and communications between different devices and systems. As an important component of the Internet of Things, PLC gateway plays an important role in smart factories.

1. Introduction to SPS-Gateway

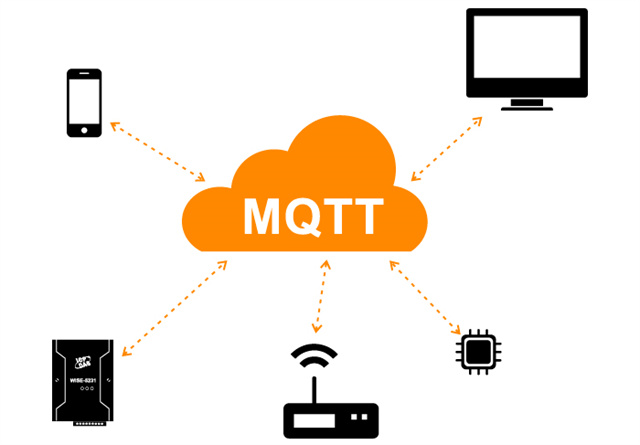

PLC (Programmable Logic Controller) is a common industrial control equipment. It has the characteristics of high performance and high reliability and is often used in industrial automation control systems. The PLC gateway is a bridge that connects PLC to other devices or systems. It realizes data interaction between different devices and systems by converting PLC signals into signals of other standard protocols.

2. Application of PLC gateway in the Internet of Things

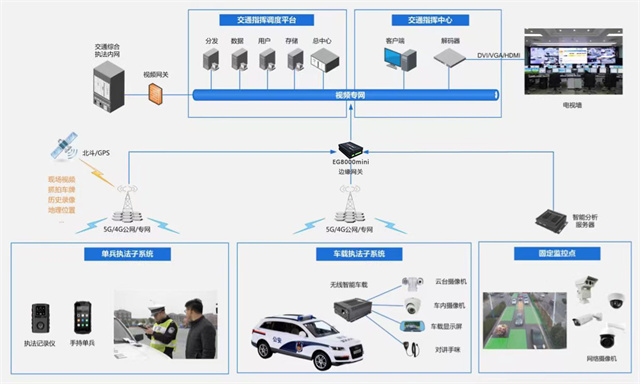

1. Data collection and monitoring: Connect various sensors and PLC equipment to collect and monitor data in various aspects of the factory in real time, such as temperature, humidity, pressure, etc., and use the Internet of Things platform for real-time display and remote monitoring to help companies discover and solve problems in a timely manner problems and improve production efficiency and quality.

2. Device linkage and control: Data sharing and interactive control can be carried out between different devices to realize device linkage and collaborative work. For example, when a certain equipment fails, the PLC gateway can automatically stop the operation of the related equipment to avoid larger problems.

3. Energy saving and optimization: By collecting and analyzing data from production equipment and systems, we help companies discover the potential for energy saving optimization. By adjusting working parameters and optimizing control strategies, energy consumption can be reduced, equipment utilization improved, and energy conservation and emission reduction goals achieved.

4. Remote maintenance and management: Realize remote monitoring and maintenance management of factory equipment, greatly improving management efficiency and response speed. Even if they are not on site, engineers can diagnose and troubleshoot equipment through the IoT platform to avoid production shutdowns caused by equipment failure.

3. PLC gateway assists in the construction of intelligent chemical plants

1. Improve production efficiency and quality: collect and monitor data in all aspects in real time, optimize processes through data analysis, and improve production efficiency and product quality. At the same time, through equipment linkage and optimization, the level of production automation is further improved and the impact of human operations is reduced.

2. Realize resource sharing and collaboration: Realize data sharing and interactive control between devices, realize collaborative work between devices, and avoid repeated operations and waste of resources. Through the Internet of Things platform, equipment and information can be interconnected within the enterprise, improving the level of comprehensive management.

3. Refined and intelligent management: Through PLC gateways and IoT platforms, companies can remotely monitor and maintain production equipment to achieve truly intelligent management. Through the data collection and analysis of PLC gateway, enterprises can grasp the production situation in time, adjust process parameters and control strategies in real time, and improve the speed of management response and the accuracy of decision-making.

Conclusion: The application of PLC gateway in the Internet of Things brings more possibilities to the construction of intelligent factories . It realizes data collection, sharing and analysis by connecting different equipment and systems, optimizes production processes and resource allocation, and improves production efficiency and quality. In the future, with the continuous development and maturity of IoT technology, PLC gateways will play an even more important role in smart factories.