There is no fastest, just faster. WIFI6 has just become popular, and WIFI7 is here.

Following the launch of WIFI6 (802.11ax), the new standard 802.11be (Extremely High Throughput) was proposed. By analogy, the WIFI Alliance will name the 802.11be standard WIFI7.

Information technology is changing with each passing day, which has benefited mankind and made electronic and chip workers miserable. But it is precisely because of this kind of hardship that we industrial workers have opportunities.

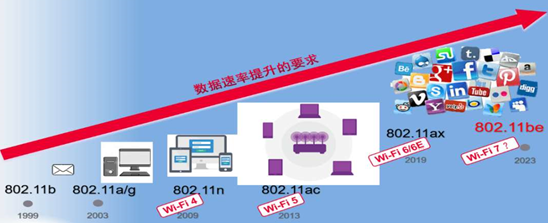

WIFI technology began in 1999 and took 4 years from 802.11b to 802.11a/g. By 2009, the 802.11n WIFI standard was officially preliminary and named WIFI4. From WIFI4 to WIFI5, it took another 4 years to open the 802.11ac standard. It will take 6 years to go from WIFI5 to WIFI6/6E, and the initial new standard is 802.11ax. 2020 is the first year of WIFI6. Although the 802.11be standard has been launched, the actual commercialization of WIFI7 is expected to be 4-5 years later.

Origin: Keysight Technologies

From the initial 1Mbps to the current 802.11ax (Wi-Fi6) peak rate of 9.6Mbps. The iteration of technical standards mainly improves the throughput and performance of WIFI data transmission through mechanisms such as bandwidth expansion, channel coding power improvement, MIMO technology, and data link layer improvement.

OFDMA multiple access technology can improve the delay problem caused by full user access and reduce network congestion caused by the channel competition mechanism. The OFDMA multi-access system divides the transmission bandwidth into a series of orthogonal and non-overlapping sub-carrier sets, and allocates different sub-carrier sets to different users to achieve multiple access. The OFDMA system can dynamically allocate available bandwidth resources to users in need, making it easy to optimize the use of system resources. Since different users occupy non-overlapping subcarrier sets, under ideal synchronization conditions, the system has no interference between multiple households, that is, no multi-access interference (MAI).

The IEEE organization has planned to conduct in-depth research on the physical layers such as frequency, bandwidth, frequency band or channel aggregation and propose a new WIFI based on the OFDMA multi-access mechanism of Wi-Fi 6 and other related technologies in order to continue to improve performance. Standard IEEE 802.11be standard.

Origin: Keysight Technologies

The closer you go to WIFI6 and WIFI7, the higher the requirements for the radio frequency front-end and the higher the process requirements.

WIFI4, 802.11n:

2.4G routers have entered thousands of households. The opportunity for the radio frequency front end is 2.4G FEM, which is mainly due to the demand for high power. Medium and low power have now been integrated. Skyworks and Qorvo no longer update products of this standard, and early products are selected Gallium arsenide process.

WIFI5, 802.11ac:

This standard introduces the 5.8GHz frequency band, opening up 2.4G and 5.8G dual-band routers. Radio frequency front-end opportunities include 2.4G FEM and 5.8G FEM.

2.4G FEM was initially added to every router. Later, the RF front-end output power integrated into the router platform could reach 19~20dBm, so it was basically not added. Skyworks has supplied 2.4G FEM with gallium arsenide and 2.4G FEM with silicon germanium (SiGe) process. Qorvo insists on gallium arsenide technology.

5.8G FEM, Skyworks first launched the 5.8G FEM using gallium arsenide process 7 years ago, with an output power of 20dBm@EVM-35dB. Later, I made a 2*2 packaged silicon germanium (SiGe) process 5.8G FEM. It looked like it was unsuccessful. The cost was pretty good, but the performance was a little worse. Qovor insists on making gallium arsenide process 5.8G FEM. Later, the MTK platform adopted the DPD function, and the output power of the integrated 5.8G FEM was also reached to 19dBm, and there were fewer opportunities to add 5.8G FEM.

WIFI6, 802.11ax:

For 2.4G FEM, Skyworks and Qorvo have all unanimously switched to silicon germanium (SiGe) process, and the performance has been tested quite well. GF is still the best in silicon germanium (SiGe) technology and is also the foundry chosen by foreign manufacturers. Silicon germanium (SiGe) process R&D costs are high and design is difficult. Domestic R&D talents familiar with this process are scarce. The advantage is that the simulation in the planning stage is relatively accurate and the production consistency is high. However, the cost comparison is about the same as that of gallium arsenide. The current of the FEM developed using the silicon germanium (SiGe) process is slightly better. Compared with the latest FEM of SKY, the gallium arsenide WIFI6 FEM developed by Sanwu Micro has an operating current of 150mA@3.3V@DVM-43dB, while the operating current of SKY FEM The current is 135mA@3.3V@DVM-43dB, a difference of 15mA.

5.8G FEM, Skyworks and Qorvo all use the gallium arsenide process. Foreign research and development experience of these two processes is that both processes can be done, but the silicon germanium (SiGe) process is always inferior to the gallium arsenide process. Click. As the requirements for design and performance get higher, the silicon germanium (SiGe) process becomes more and more inadequate, and the gallium arsenide process has to be adopted.

In terms of WIFI6 main chip technology, especially the underlying software protocol, MTK is still far away from Qualcomm and Broadcom. The distance between domestic chip manufacturers is even greater. It will be very good if China can mass-produce WIFI6 main chips in 2 years. MTK’s advantages are also obvious, with balanced technology. It is very good in baseband chips, software protocols, radio frequency transceivers, radio frequency front-end and other technologies, especially in the world’s leading radio frequency front-end technology.

Therefore, MTK WIFI6 low-end solution does not need to use 2.4G WIFI6 FEM and 5.8G WIFI6 FEM, and the RF front-end is fully integrated to complete power output. Qualcomm and Broadcom can’t do it, and other domestic manufacturers can’t do it even more.

Of course, with the arrival of WIFI6, the frequency bands of different countries have changed. my country has remained unchanged and it is expected that it will not change in the future. However, the United States and Brazil have expanded the WIFI frequency band to 7.2GHz, and Japan may follow suit. Europe has raised the frequency band to 6GHz. Due to changes in the frequency band, the WIFI FEM front-end chip also needs to be modified. The higher the frequency, the wider the bandwidth, and the higher the requirements for design and process. The process choice is still gallium arsenide. At the same time, the difficulty of integrating the RF front-end is gradually increasing.

WIFI7, 802.11.be:

2.4G FEM, silicon germanium (SiGe) process and gallium arsenide process will all exist.

Personally, I think 5.8G FEM can only be made using gallium arsenide technology. It is more difficult to integrate the RF front-end into the main chip, and FEM plug-ins will be the mainstream.

The higher the frequency, the wider the bandwidth, and the faster the speed, the more difficult it is to develop a chip. The gallium arsenide process still has relatively advantages, so gallium arsenide will be the mainstream process and future direction of WIFI FEM.

Although MTK is very powerful and continues to challenge integrated radio frequency front-ends, the fact is that the market demand for WIFI FEM is not getting smaller and smaller, but is gradually getting larger. For the router market, integration will not be the mainstream. As WIFI technology continues to develop, market applications are becoming more and more widespread, and the requirements for RF front-ends are gradually increasing. There are many opportunities for RF front-end FEM.

*Disclaimer: This article is original by the author. The main content of the article is the author’s own opinion. The reprint of Semiconductor Work Inquiry is only to convey a different point of view. It does not mean that Semiconductor Work Inquiry agrees or supports the concept. If you have any objections, please contact Semiconductor Work Inquiry.

Source: The content is reproduced from the public account “Zhong Lin Tan Xin”, author: Zhong Lin, thank you.

Related recommendations: RS232