Coal has always been the main energy source in China, and coal mine geological monitoring is an important guarantee for safe production in coal mines. Distributed optical fiber sensing technology has the advantages of continuous sensing points, high precision, anti-electromagnetic interference, corrosion resistance, etc., and plays an important role in coal mine geological monitoring. Application. This article introduces Brillouin optical time domain reflectometry,

BOTDR) technology in coal mine geological monitoring. This article focuses on the methods and results of using distributed optical fiber sensing technology to monitor ground deformation in goaf areas. The results show that distributed optical fiber monitoring technology can meet the needs of coal mine geological monitoring and has Good application prospects.

Coal is an important main energy source in China, occupying an important strategic and dominant position in the energy supply structure. China has abundant coal resource reserves, with predicted geological reserves exceeding 4.5 trillion tons. Coal accounts for 60% of the primary energy production and consumption structure all year round.

Above, by 2020, the total domestic primary energy consumption will be controlled at approximately 4.8 billion tons of standard coal, and coal consumption will be controlled within 62% [1]

. It is expected that coal will still account for 50% of primary energy production by 2050[2]

. The energy structure dominated by coal will not change for a long time. The development and utilization of coal resources is an inevitable choice for energy endowment, energy structure and economic and social development.

In the life cycle of coal mining, realizing green mining and safe production of coal is a top priority related to the sustainable and healthy development of the coal industry. Therefore, coal mine geological support technology and equipment, as one of the key technologies for efficient, safe and green development of coal mines, are listed as Five guarantee systems for entering high-yield and efficient mines.

With the continuous reduction of China’s shallow coal resource reserves, the depth of coal mining is gradually developing towards the deep[3]

. Deep tunnels are under special geological conditions of high geostress, high temperature, and high permeability [4], which can easily cause severe tunnel deformation and stope pressure, which can lead to rock bursts, rock burst accidents, and coal and gas outburst accidents. , the probability of water inrush accidents increases [5], seriously affecting the safety production of coal mines. At present, geological survey, geophysical prospecting, drilling, chemical prospecting and other technologies are usually used to solve coal mine geological problems such as coal gang structure, gas occurrence, water damage prevention and control, and ensure the safety of coal mines. safe production[6]

. The above-mentioned technologies have played an important role in coal mine geological assurance, but there are also problems such as short sensor service life, potential safety hazards in electrical sensors, and difficulty in real-time measurement.

Distributed optical fiber sensing technology has the characteristics suitable for engineering applications such as continuous distribution of sensing points, resistance to electromagnetic interference, high strain measurement accuracy, good toughness, strong resistance to deformation and wear, and is very consistent with the application needs of geological and engineering safety monitoring [7 -9]

. In recent years, researchers have used distributed optical fiber sensing technology to carry out safety monitoring of oil and gas pipelines [10], geotechnical engineering safety monitoring [11], oil exploration [12], and transmission line safety monitoring [13]. Research and application have been carried out to varying degrees. This article introduces some applications of distributed optical fiber sensing technology in current coal mine geological monitoring, and provides solutions for monitoring ground stability in coal mine goafs.

Applications.

1 Distributed optical fiber sensing principle

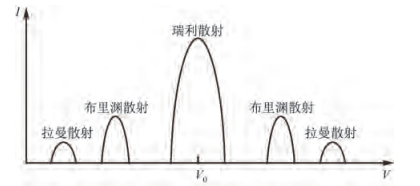

Light waves interact with particles in the optical fiber medium to produce scattering. Scattered light in optical fibers includes Rayleigh scattering

scattering), Brillouin scattering (Brillouin scattering), Raman scattering (Raman scattering), as shown in Figure 1.

Brillouin scattering is produced by the interaction between photons and acoustic phonons. Due to the Doppler effect, the Brillouin scattered light has a Brillouin frequency shift νB relative to the incident light. When the detection pulse light is injected into the sensing fiber bl, the back-Brillouin astigmatism generated at each position along the fiber returns to the fiber incident end along the original path of the fiber, and there is a good linear relationship between the value of νB at each position and the strain of the fiber at that position. , can be expressed as

In the formula, vB(ε) is the drift of the Brillouin frequency actually measured, vB (0) is the drift of the Brillouin frequency when the strain is 0, dvB(ε) dε is the proportional coefficient, at 1 The value of the 550 nm wavelength is approximately 493 MHz/%. By measuring the frequency drift vB of the back-Brillouin scattered light in the optical fiber, the strain distribution information along the optical fiber can be obtained, thereby realizing distributed optical fiber strain sensing. In Among the currently more mature distributed optical fiber strain sensing technologies based on Brillouin scattering, Brillouin optical time-domain reflectometry (BOTDR) technology is based on the principle of optical time-domain reflectometry and spontaneous Brillouin scattering. , can achieve single-ended detection without providing loop optical fiber, which has obvious advantages in geotechnical and geological engineering. The testing distance of currently commercial BOTDR instruments can usually reach tens of kilometers, and when the spatial resolution is in the order of m, answer

The variable test accuracy can be guaranteed to be in the order of tens of με. Keywords: remote control RTU