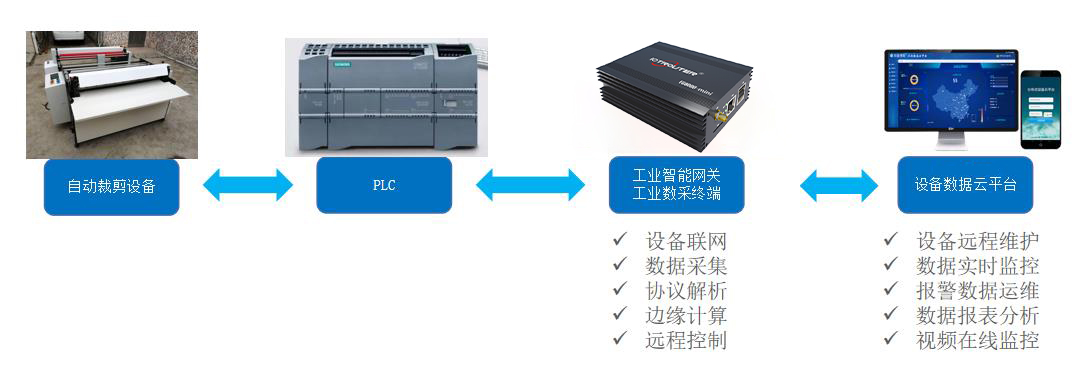

PLC-controlled automatic cutting equipment is suitable for cutting various materials. It can control the moving speed, moving stroke, length and quantity of cutting materials, etc., which can greatly improve work efficiency and save a lot of labor costs. By collecting data through the industrial intelligent gateway and uploading it to the monitoring platform, the production process and equipment operating status can be remotely monitored, which is an important issue that must be solved to achieve digital management in the factory.

The automatic cutting equipment controlled by PLC can be connected to the industrial intelligent gateway through the serial network port. The gateway performs protocol analysis and data collection, and uploads the equipment data collection to the monitoring platform (local host computer, cloud platform, touch screen, etc.) for remote monitoring. Quick alarms on equipment operating status and equipment failures and remote maintenance can effectively ensure cutting efficiency and finished product quality.

Ventajas del sistema

1. Data collection

The gateway supports the collection of PLCs of various brands (Siemens, Mitsubishi, Omron, Schneider, Delta, Inovance, etc.), has a rich built-in protocol library, automated protocol analysis and data collection, and supports 5G/4G/WIFI/Ethernet and other Internet module options. .

2. Real-time monitoring

The data supports transmission to third-party clouds such as Zongheng Cloud, self-developed cloud, Alibaba, Baidu and Huawei, touch screens, local PCs, etc. for real-time monitoring. Various technical parameters are updated in real time, and the equipment operating status is clear and clear.

3. Fault alarm

By setting alarm rules and notification methods, when abnormal data is collected, the system will automatically generate alarms and push them to managers. WeChat, SMS, email, etc. are supported to quickly understand alarm equipment and fault information.

4. Remote maintenance

Without the need for business trips or additional expenses, engineers can remotely upload and download programs and remotely program and debug remote PLCs, quickly complete PLC maintenance work, and maintain a safe and stable production rhythm.