PLC gateway construction is an indispensable key technology in modern industrial control systems. With the continuous development of industrial automation, more and more companies are realizing the importance of the reliability and efficiency of control systems to their business. As one of the key components of the industrial control system, the PLC gateway can realize interconnection and interoperability between different control devices, greatly simplifying the system integration process and improving work efficiency.

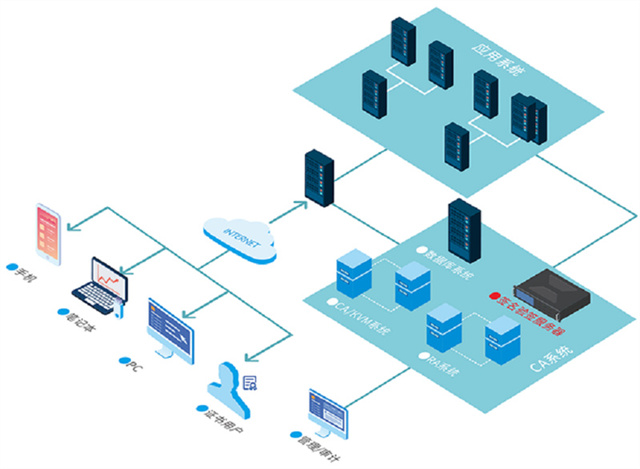

Although the application scenarios of Pasarela PLC construction technology are different in different industries, the core ideas are the same. By connecting different control devices (such as PLC, remote I/O, sensors, etc.) to the PLC gateway, these devices can be centrally managed and controlled to realize data transmission and sharing. This allows engineers to monitor and control the entire system through a unified interface without having to face complex configuration and interface issues for different devices.

In modern industrial control systems, engineers usually face compatibility issues between different communication protocols and devices. The emergence of PLC gateway solves these problems. Data communication and conversion between different devices can be achieved through PLC gateway. In addition, PLC gateway can also support multiple communication protocols, such as Modbus, OPC UA, etc., allowing engineers to easily establish communication links between different devices. In this way, engineers can focus more on writing control logic and optimizing the system without paying too much attention to the underlying communication details.

It is worth mentioning that with the development of software-defined network (SDN) technology, PLC gateway construction has entered a new stage. SDN technology provides a more flexible and programmable network architecture by decoupling the network control plane and the data forwarding plane. In the application of PLC gateway, SDN technology can greatly simplify network configuration and management work, and improve the flexibility and scalability of the system. For example, through SDN technology, engineers can centrally manage the entire network through a centralized controller to achieve remote configuration and monitoring of PLC gateways. In addition, SDN technology also supports fast fault recovery and network traffic management, thereby improving system reliability and performance.

To sum up, PLC gateway construction is an important technology in modern industrial control system integration, which can simplify the system integration process and improve work efficiency. At the same time, combined with software-defined network technology, the functions of the PLC gateway are further enhanced, achieving flexibility and scalability in network configuration and management. In the future, with the continuous development of industrial automation, PLC gateway construction technology will be applied in more fields, providing engineers with better tools and solutions.