The RTU valve chamber is a vital component in automation engineering. As the core control center of the project, the function of the RTU valve chamber cannot be underestimated. So, what is an RTU valve chamber? What does it do?

RTU valve chamber, the full name of telemetry terminal unit valve chamber, is a key node used to control and monitor industrial processes. It typically contains equipment such as valves, cables, sensors, computers, and monitoring systems. The RTU valve chamber realizes automated operation and monitoring of industrial processes by centrally controlling and monitoring these devices.

RTU valve chambers play an important role in the field of industrial automation. It can not only improve work efficiency and production quality, but also reduce the impact of human factors on process control and process stability. Through the RTU valve chamber, engineers can understand the data and status of the industrial process in real time, adjust parameters in a timely manner, and improve the reliability and stability of the process.

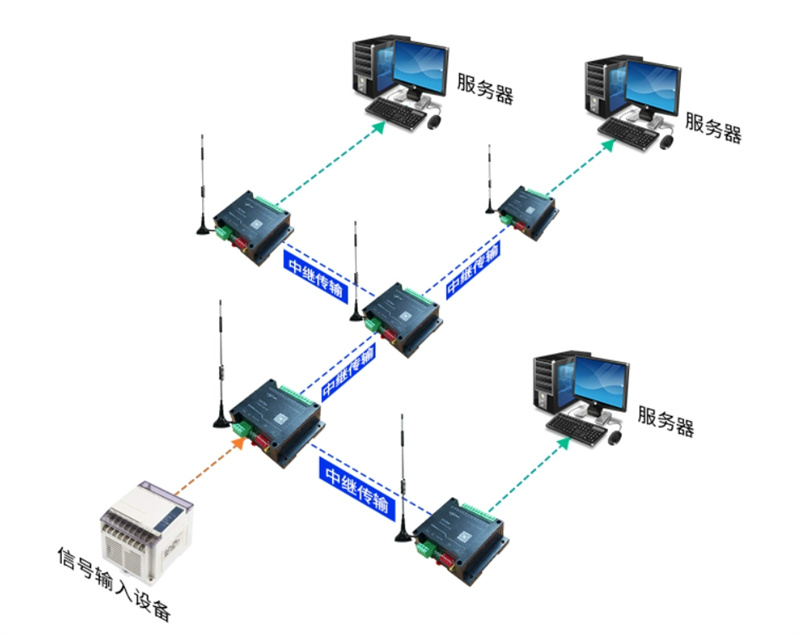

In practical applications, RTU valve chambers are often combined with on-site monitoring systems. The data collected through the sensor can be transmitted to the RTU valve chamber in real time, thereby realizing online monitoring and control of process parameters. At the same time, the RTU valve chamber can transmit the collected data to the host computer or cloud server for remote monitoring and analysis by managers. This centralized control and remote monitoring model not only improves project management efficiency, but also reduces operation and maintenance costs.

In order to protect the normal operation of the RTU valve chamber and the safety of the equipment, engineers need to take a series of measures. The first is to use fireproof materials and lightning protection equipment to prevent damage to equipment caused by fire and lightning strikes. The second step is to conduct regular equipment inspections and maintenance to detect faults and repair them in a timely manner. Additionally, communications should be encrypted and permission controls set up to prevent external attacks and unauthorized operations.

In short, the RTU valve chamber is an important equipment in industrial automation engineering. It not only realizes the automated operation and monitoring of industrial processes, but also improves work efficiency and production quality . By combining with on-site monitoring systems, engineers can understand and adjust parameters in industrial processes in real time to ensure the reliability and stability of the process. However, in order to protect the operational safety of the RTU valve chamber, engineers still need to take corresponding protective measures. Only in this way can we make better use of the advantages of the RTU valve chamber and promote the development of industrial automation.