The demographic dividend, one of the huge advantages on which my country’s economic development and manufacturing industry depends for its success, is being lost. Under the influence of internal and external factors such as difficulties in innovation and upgrading and weak foreign economies, many traditional enterprises began to suffer losses or even went bankrupt, and the development of China’s manufacturing industry encountered a bottleneck. Against the background of a weak global economy, the transformation and upgrading of the manufacturing industry and the trend of digital economy are becoming increasingly clear, and the wave of industrial Internet is surging fiercely. The Industrial Internet is generally regarded as the “Fourth Industrial Revolution”. The United States, China, Germany, Japan and other major industrial countries in the world are seizing the important opportunities of the strategic layout of new manufacturing industries. How can China’s manufacturing industry and even the construction machinery industry seize the opportunity? seize this important strategic opportunity? What are the difficulties we face? What is the difference between Industrial Internet and Industrial Internet of Things? What is industrial big data and industrial control big data? How to get to the cloud? What changes will the 5G era bring to the industrial Internet? These questions are worthy of our consideration.

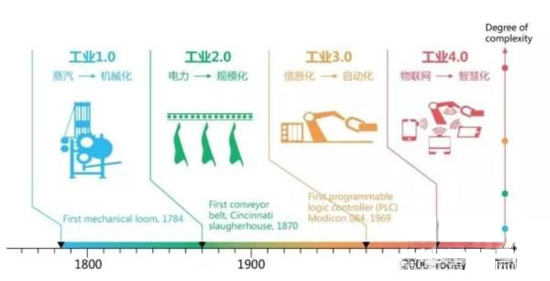

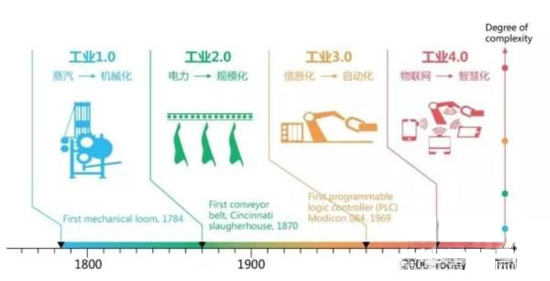

The evolution of the industrial revolution and the origin of Industry 4.0

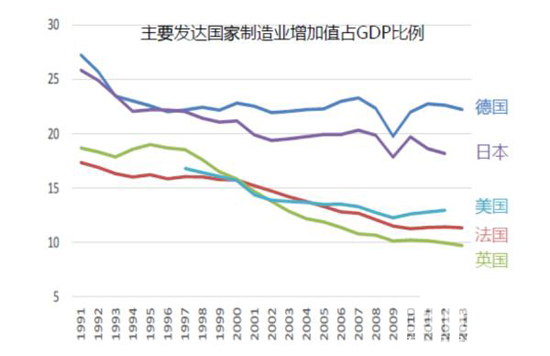

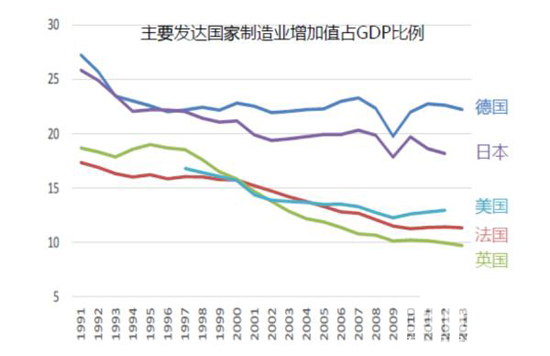

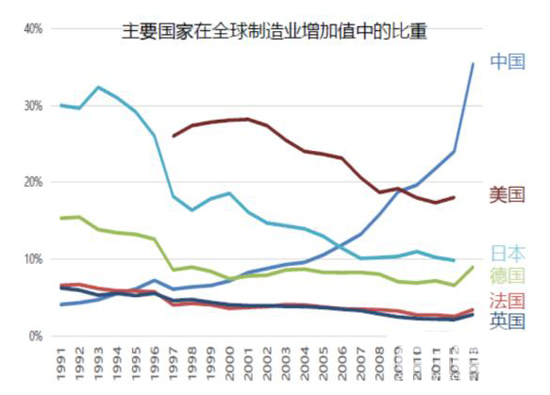

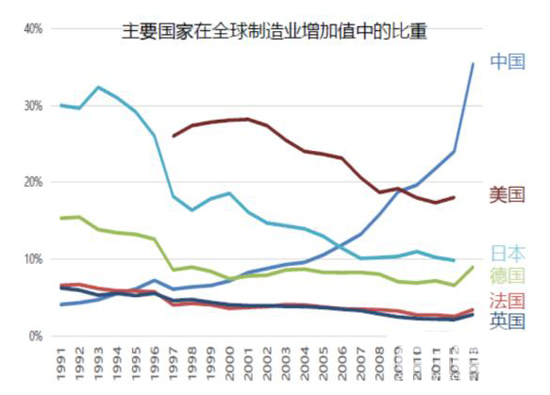

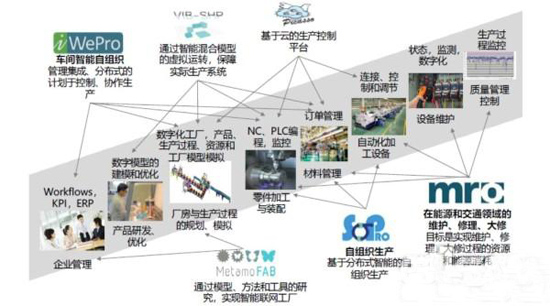

Global emerging manufacturing strategic layout map

Dilemma of traditional manufacturing model

After hundreds of years of development, traditional manufacturing models and systems have become very mature, but they still face many difficulties.

First, the manufacturing cost advantage is gradually lost

In the past few decades, China’s economy has basically followed an extensive development model, and the same is true for its manufacturing industry. Chinese manufacturing companies often rely on abundant and low-cost raw materials and labor, and earn a small amount of processing fees by processing products for foreign companies. However, in recent years, with the rise in inflation and raw material prices, the demographic dividend has disappeared and cost pressure has become prominent. The improvement of cost control is close to the limit and cannot effectively respond to flexible and changing market demands.

Second, overcapacity

Overcapacity is also a challenge restricting the development of my country’s manufacturing industry. Judging from the current domestic situation, the overcapacity situation in the general industrial product market is becoming more and more obvious, and product homogeneity is serious. In addition, under the impact of factors such as the manufacturing strategic plans of developed countries and the cost impact of backward countries, China’s manufacturing export orders have dropped sharply, and external export demand has declined, further exacerbating the overcapacity situation.

Third, there is a lack of high-level management and production efficiency needs to be improved.

1. The design, production, and management of manufacturing enterprises in my country are often one-way driven. Production tasks are decomposed step by step, and production schedules and processing parameters cannot be dynamically optimized based on on-site production conditions. Product design and manufacturing services are advanced step by step, and product design cannot be improved in a timely manner based on manufacturing and services.

2. At the same time, there is a lack of efficient collaboration between design and production management. Rigid equipment and production lines cannot be flexibly adjusted according to product design changes, and rigid resource organization and production plans cannot be flexibly adjusted according to product changes.

3. Enterprises make more decisions based on experience. People-centered, experience-based decision-making and optimization cannot achieve more accurate judgments.

4. Limited scope resource organization. In terms of scope, it is mainly based on internal resources of the enterprise, and it is unable to effectively integrate excellent resources distributed around the world at low cost; in terms of form, it is mainly based on procurement methods, lacking efficient and close collaboration among different entities.

my country’s manufacturing industry needs a clear positioning. It should get rid of factor-driven factors (labor factors, resource factors, land factors, capital factors) as soon as possible, transform and develop towards efficiency-driven (investment-output ratio, return on investment), and become innovation-driven (taken by the United States and Germany). (to represent the development of the manufacturing industry) and transform the manufacturing industry through innovation-driven development.

While traditional manufacturing is encountering the above difficulties, the arrival of the Industrial Internet comes at just the right time. But do we really understand the Industrial Internet?

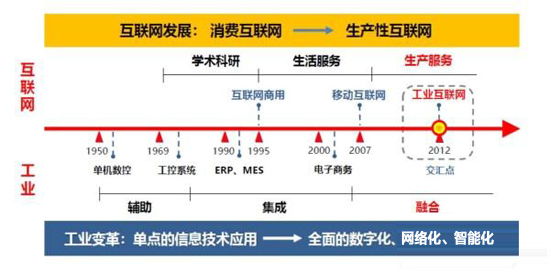

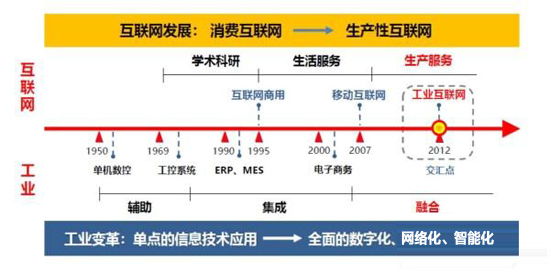

The rise of the industrial Internet

What is the potential of the Industrial Internet?

According to the 2017 Internet of Things investment expenditure forecast released by IDC, the three major industries in the world that are preparing to invest before 2020 are all part of the industrial Internet market. According to data from CCID Consulting, China’s industrial Internet of Things market size was 189.6 billion yuan in 2016. By 2020, the industrial Internet will account for 25% of China’s overall Internet industry, with a scale exceeding 450 billion yuan. According to speculation by relevant agencies, in the next 15 years, the scale of my country’s industrial Internet will reach 1.8 trillion U.S. dollars, with huge room for development.

The global digital economy wave in the past 10 years

With an average annual growth rate of nearly 20%, my country has become the country with the fastest growing industrial Internet. This has also given rise to many concepts: Industrial Internet of Things, Industrial Internet, Intelligent Cloud Network, Industrial Big Data, etc. Many people are confused about them. connections and differences between them.

Industrial Internet of Things VS Industrial Internet

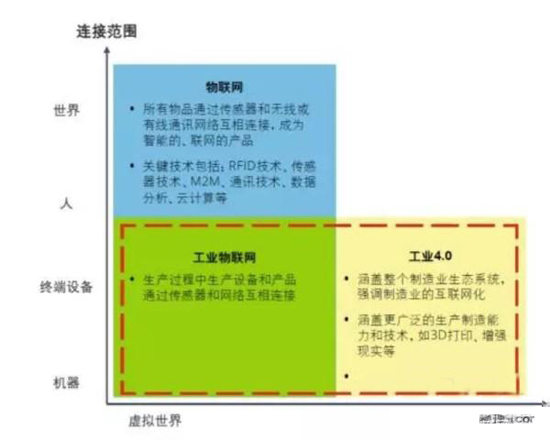

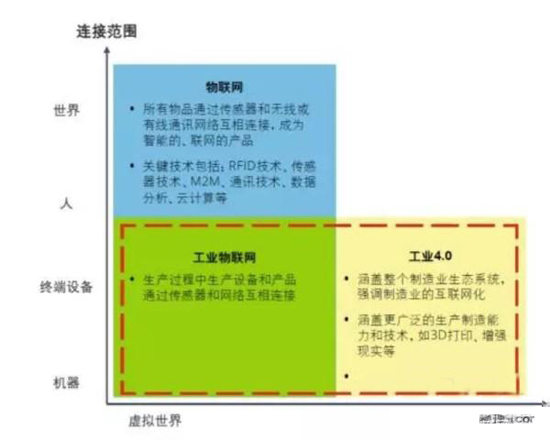

The Industrial Internet and the Industrial Internet of Things can basically be considered the same concept, but there are certain connections and differences between them, mainly as follows:

First, we must distinguish between the concepts of the Internet and the Internet of Things.

The Internet is an international computer network composed of wide area networks, local area networks and stand-alone computers according to certain communication protocols. The Internet refers to the result of connecting two computers or more than two computer terminals, clients, and servers through computer information technology to solve the problem of interconnection between people. People can obtain information and publish information on the Internet. Reviews, purchasing products, purchasing services, etc. However, these information and services require a lot of work for people to complete, and it is difficult to understand their changes dynamically.

The Internet of Things (IoT, Internet of Things) is defined as the use of various information sensing devices, such as radio frequency identification (RFID) technology, global satellite positioning systems, infrared sensors, laser scanners, gas sensors and other devices With technology, real-time collection of any object or process status information that needs to be connected, monitored, and interacted includes its sound, light, heat, electricity, mechanics, chemistry, biology, location and other basic information, forming an interactive and interactive system through the Internet. The purpose of an identifiable and shareable network is to realize the connection, identification, management and control of things and things, people and things on the network. The information of the Internet of Things is dynamic and mainly generated by physical machines.

There is a connection between the Internet and the Internet of Things. First, the communication channel of the Internet of Things is still the Internet, which is a network that extends and expands to the sensing layer based on the Internet; second, Internet of Things users can extend and expand end-to-end and expand to any things and things through the communication channels of the Internet. between people and things.

Looking further, the Industrial Internet cannot simply be understood as the Internet in the industrial field. If we only separate the two keywords of industry and Internet to understand, it can easily be understood as the Internet used in the industrial field. This understanding is still the concept of the Internet. . The Industrial Internet of Things can basically be understood as the Internet of Things in the industrial field.

On the other hand, there are both overlaps and differences between concepts such as the Industrial Internet of Things and Industry 4.0. With the deep integration of industrialization and informatization, the demand for interconnection within enterprises is increasing. The demand for improving product quality and operational efficiency through access to the network is even stronger. The Industrial Internet of Things (IIoT, Industrial Internet of Things) has emerged. And born.

The Industrial Internet of Things turns every link and equipment in the production process into a data terminal, collects underlying basic data in an all-round way, and conducts deeper data analysis and mining to improve efficiency and optimize operations.

What is industrial big data

The development of industrial big data has caught up with the good times, and the development of related technologies has made the rapid development of industrial big data possible. Nowadays, sensors have become ubiquitous, the computing and carrying capabilities of platforms have been continuously enhanced, technologies such as artificial intelligence have made data analysis more efficient, and the active IoT (Internet of Things) ecosystem has allowed more and more companies to try to Realize data value through APP microservices.

Generally speaking, big data can be divided into industrial big data and Internet big data. Big data in a narrow sense refers more to Internet big data. At present, in terms of technology and applications, the development level of Internet big data is even more advanced.

Industrial big data draws on the concept of Internet big data and combines it with IoT technology to expand the “behavioral” data analysis and thinking model for individual users and apply it to the enterprise field.

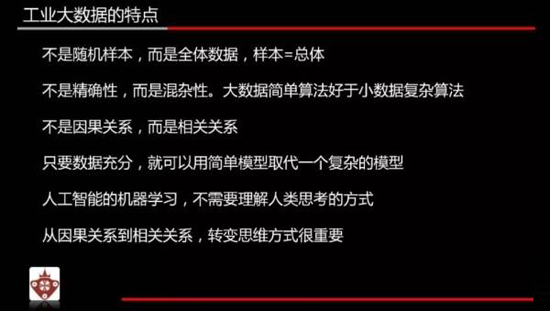

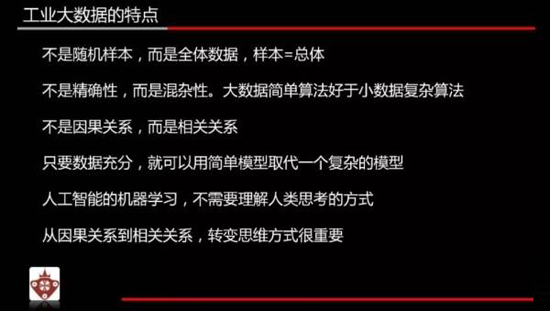

Industrial big data has its own characteristics: most of it is time series data, which is quite different from the Internet big data we usually talk about.

First, industrial big data originates from within the enterprise, not from individual Internet users;

Secondly, the data collection method relies more on sensors rather than user behavior or data entry;

Third, the data service targets enterprises, not individuals;

Fourth, in terms of technology, traditional enterprise IT technology can no longer provide corresponding analysis applications, and it is necessary to learn from and adopt mature technologies in the field of Internet big data;

Fifth, industrial big data allows enterprises to change their original views on data, allowing seemingly useless and directly discarded data to regain their attention, and effectively improve the enterprise’s production, sales, service and other processes.

The difference between industrial big data and Internet big data

Four stages of industrial Internet development

The Industrial Internet is a process of gradual development and maturity, including 4 stages in implementation:

1. Intelligent perception control stage

That is, terminal-based intelligent sensing technology, such as sensors, REID, wireless sensor networks, etc., is used to collect industrial data and intelligentize equipment control at any time and anywhere.

2. Comprehensive interconnection stage

Through a variety of communication network interconnection methods, such as passerelles industrielles, short-distance wireless communications, low-power wide area networks, and OPCUA, we integrate common information technology and industry characteristics to transmit the collected data in real time and accurately.

3. In-depth data application stage

That is, using cloud computing, big data and other related technologies to model, analyze and optimize data, realize in-depth development and application of multi-source heterogeneous data, extract hidden predictive information from the data warehouse, and discover potential relationships between data , quickly and accurately find valuable information, and effectively improve the system’s decision support capabilities.

4. Innovative service model stage

Utilize technologies such as information management, intelligent terminals and platform integration to provide customized services, value-added services, operation and maintenance services, upgrade services, training services, consulting services and implementation services to realize the intelligent transformation of traditional industries, enhance industrial value and optimize services. resources and stimulate industrial innovation.

The implementation path of German Industry 4.0

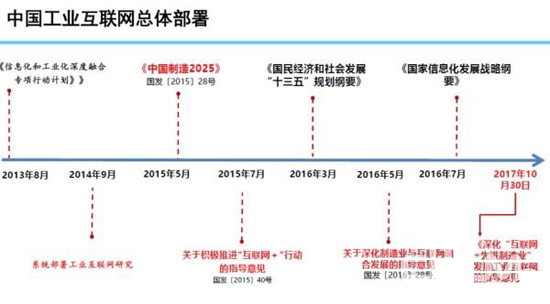

The overall deployment of China’s industrial Internet

The Industrial Internet is widely known as the “Fourth Industrial Revolution”. Whether our country can seize the opportunity of this industrial revolution is of great importance. The author has seen someone compare China to a giant dragon of diversified development. The dragon’s head has entered the information age of the 21st century, the dragon’s body is still in the industrialization era, and the dragon’s tail is still in the agricultural era. This description is very appropriate. my country’s manufacturing industry is also diversified and long-chain. This characteristic has created a historical opportunity for the industrial Internet to drive the transformation and upgrading of China’s manufacturing industry. We need to understand and learn more and take further advantage of this opportunity.