Introduction:

Usually the parameters we see in the computer terminal screen: voltage, current, frequency, etc. are all digital signals. To convert the basic parameters into digital signals requires a complex process. This process is referred to as the analog channel. This article will become The impact of transmitter collection of basic parameters and analog transmission on digital terminal display is briefly analyzed, and the relationship between the two is analyzed, and the practical significance of the two in production operation is analyzed. As the main interface for centralized control operation of thermal power plants, DCS has become a control system widely adopted by thermal power plants that integrates monitoring, alarming, accident handling, and automatic control due to its stability, plasticity, operability, and economy. mode, and digital signals are the basis of DCS control. If the screen data display is inaccurate, it will bring great difficulties to the operation control. The task of the analog input channel is to convert the basic parameters collected by the transmitter such as temperature, pressure, current and other signals through the signal conditioning circuit, select multiple analog switches, and amplify the preamplifier to the range of the A/D converter. Sample and hold, A/D conversion, interface logic judgment, and finally conversion into a digital signal for display. This is the overall process of the entire analog channel. This article will start with the transmitter, select the voltage transmitter, the simplest type of transmitter, and analyze the impact on the analog channel based on its abnormal operation.

1 Principle of voltage transmitter

AC voltage transmitter is composed of voltage transformer, precision rectifier filter, and vi conversion circuit. The voltage transformer converts the AC voltage from 0v to 100v into the required AC voltage signal. The precision rectifier circuit amplifies and rectifies the AC voltage signal into a relatively stable DC voltage. Afterwards, the vi converter converts the stable DC voltage signal into a constant proportional current output. The ultimate goal is to convert AC power with an effective value of 0v ~ 100v into a DC current output of 4ma ~ 20ma (≤ 200Ω load).

2 Analysis of factors affecting AC voltage transmitter output

In the power production process, there are a variety of measurement, monitoring, control and other instruments, transmitters, and operating mechanisms. Due to differences in voltage levels, frequencies, signal strengths, etc., varying degrees of interference will occur during operation. Sometimes, interference may occur. Will cause distortion of measurement data. Another factor that affects the error of each meter is the ground current. In order to ensure safe operation, many equipment require shell protection and grounding. Since the ground point of each equipment has different ground reference potential, this will inevitably cause ground circulation to flow through transmitters and other instruments. between, affecting the measurement results.

3 solutions

In order to solve the problem of abnormal operation of the transmitter due to local interference of equipment and the influence of ground circulation, resulting in inaccurate digital signal indication after the analog channel, the power plant must take corresponding protective measures to avoid distortion of the computer-side digital signal due to interference. . The main factors that affect interference are the following: interference sources, induction sources, and coupling paths. When designing and constructing a power plant, it is obviously unrealistic to consider arranging various equipment, meters, and transmission mechanisms separately due to external interference factors without considering the actual needs of production. Therefore, separate layout measures for interference sources and induction sources cannot be implemented. We can only think of ways to make a fuss from the coupling path.

3.1 Keep transmitters and instruments at equal potentials

The specific layout is to optimize the grounding system of the entire factory, and use the same grounding point layout for components that are particularly susceptible to external disturbances from ground circulation to ensure equal ground potentials and eliminate circulation currents. For example, various meters in the protection screen of the generator-transformer unit are grounded in this way to avoid influence.

3.2 Minimize or no grounding

This method is of little significance in practical applications, because equipment protective grounding and shielding grounding have their own roles, and it is obviously unrealistic to cancel grounding due to fear of errors caused by ground circulation. Moreover, many equipment may be corroded and grounded due to external environment and other factors. It is unrealistic to not be grounded at all from the perspective of the external environment.

3.3 Use signal isolator

Use a signal isolator, that is, use the signal conditioning mode mentioned in the introduction of the article, to disconnect the external ground current loop, thereby eliminating the impact of ground current on the transmission effect of the transmitter. In addition, the signal isolator has multiple channels and interfaces, and also indirectly plays the role of signal conversion and distribution, interface conversion, etc., making the entire analog channel operation mode more flexible, economical and reliable. The existence of the signal isolator is also used to limit the voltage, current, and frequency of the lower-level loop to protect the lower-level control loop by ensuring power quality. It also has a great inhibitory effect on external interference such as noise, grounding, frequency converters, capacitors, and inductors.

4 Accident handling

The interference of the transmitter will cause digital signal distortion, and the failure of the transmitter may directly cause the digital signal to be unable to be displayed. Therefore, it is necessary to study the transmitter fault judgment analysis method and processing method.

4.1 Fault judgment analysis

(1) Investigation method. Review the ignition, odor, smoke, misoperation, and mismaintenance before the failure occurred.

(2) Intuitive method. Observe the external damage of the circuit, the overheating of the circuit, the status of various switches, and whether there is any leakage in the pressure pipeline.

(3) Detection method. a. Circuit break method detection: Separate the suspected faulty part from other parts and check whether the fault disappears. If it disappears, determine where the fault is. Otherwise, you can proceed to the next step to find out. If the smart transmitter cannot communicate with HART remotely normally, you can disconnect the power supply from the meter body and power on the transmitter for communication by adding an additional power supply on site to check whether the cable is superimposed with excessive electromagnetic signals and interferes with communication. . b. Replacement method detection: Replace the suspected faulty part to determine the fault location. For example: if the transmitter circuit board is suspected to be faulty, a board can be temporarily replaced to determine the cause.

4.2 Transmitter output is too low or has no output

4.2.1 Reasons

(1) The transmitter has no voltage;

(2) The line connection is loose;

(3) There is sediment on the flange;

(4) The flange is leaking;

(5) The connector is not clean,

(6) The measuring range exceeds the adjustment range,

(7) Sensitive parts are short-circuited;

(8) The pin connection is not firm;

(9) The circuit board is faulty

(10) The power supply has no output.

4.2.2 Processing

(1) Check the voltage of the transmitter and supply power to 24VDC;

(2) Correct wiring;

(3) Disassemble the transmitter flange and rinse the dirt with clean water;

(4) If the flange O-ring is damaged, replace it and reconnect the flange;

(5) Wipe the connector with alcohol;

(6) Re-select the corresponding range transmitter or replace the sensitive parts of the corresponding range;

(7) Replace sensitive parts;

(8) Connect the pins firmly;

(9) Replace the faulty circuit board;

(10) Replace the shell.

4.3 Output is too large

4.3.1 Reasons

(1) Whether there is excessive sediment on the flange;

(2) The connector is not clean,

(3) The connection of sensitive parts is unreliable;

(4) The pin connection is unreliable;

(5) The circuit board is faulty.

4.3.2 Transformation

(1) Rincez d'abord à l'eau. S'il n'est pas possible de le nettoyer complètement, démontez la bride du transmetteur, nettoyez la saleté et réinstallez-la ;

(2) Essuyez le connecteur avec de l'alcool ;

(3) Connecter les pièces sensibles de manière fiable

(4) Connecter fermement les broches ;

(5) Remplacer la carte de circuit imprimé défectueuse.

4.4 Défaillance du circuit électrique

En raison d'une connexion virtuelle, d'un court-circuit, d'une déconnexion ou d'une mise à la terre de la ligne, il y a déviation de la mesure ou absence d'indication. Vous pouvez mesurer l'alimentation, la résistance et l'isolation à l'aide d'un mégohmmètre.La plage de mesure de la transmission de la pression différentielle est généralement relativement petite. À l'usage, la différence de hauteur entre le point de mesure et le point d'installation, ainsi que l'inclinaison à gauche ou à droite de la position d'installation, entraînent une erreur supplémentaire importante. Toutefois, en raison de la linéarité

4 Analyse des résultats et conclusion

4.1 Analyse des résultats

Le degré n'ayant pas changé, la méthode de réglage du zéro en ligne peut être utilisée pour rétablir ses performances de mesure normales, ce qui garantira son utilisation correcte dans l'automatisation et le contrôle industriels et assurera la mise en œuvre correcte et efficace du processus de production.

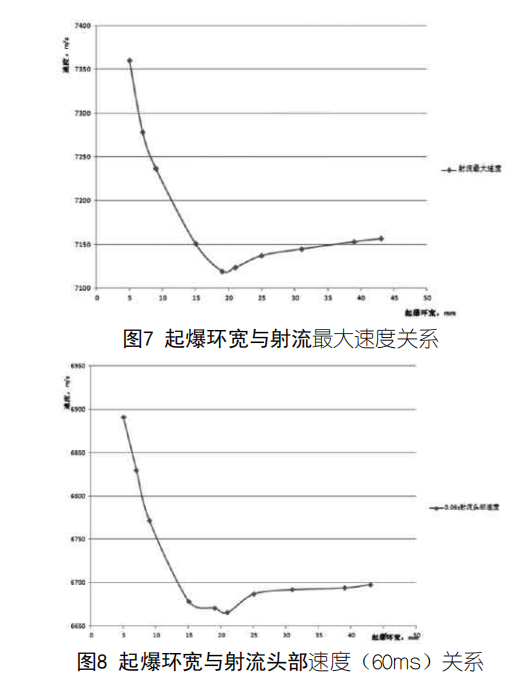

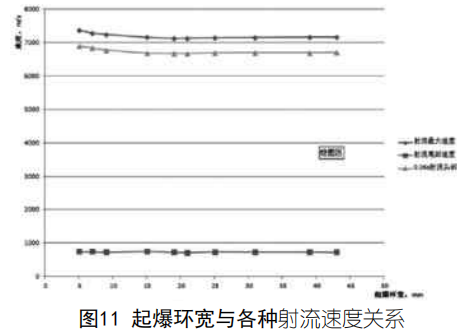

(1) Le calcul ci-dessus montre que dans le système de détonation annulaire, lorsque la largeur de l'anneau de détonation augmente, la vitesse maximale du jet et la vitesse de la tête du jet diminuent d'abord, puis augmentent.

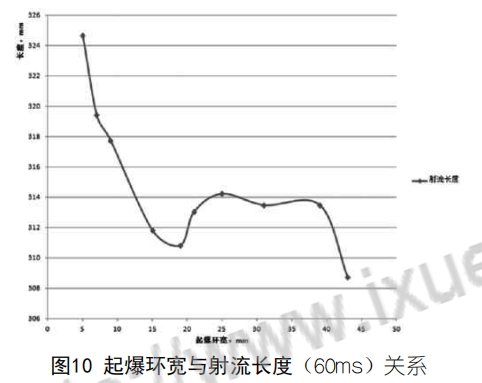

(2) La longueur du jet se réduit d'abord progressivement, puis augmente à mesure que la largeur de l'anneau de détonation s'accroît.

(3) L'analyse montre que dans le système de détonation annulaire, la formation du jet de charge creuse peut être fortement influencée par le réglage de la largeur de l'anneau de détonation dans certaines conditions. Parmi les 10 schémas, la différence de vitesse du jet est de 3,37%, et la longueur du jet est différente de 5,16%.

(4) Lorsque le système de détonation annulaire fait exploser la charge creuse pour former un jet, il contrôle la forme de propagation de l'onde de détonation dans l'explosif en modifiant la largeur de l'anneau de détonation, ce qui modifie l'angle d'incidence de l'onde de détonation sur le couvercle de la charge et agit sur la charge. La pression sur le couvercle contrôle la vitesse d'écrasement et l'angle d'écrasement du couvercle de médecine et affecte la vitesse du jet.

4.2 Conclusion Une charge creuse ayant de bonnes performances doit non seulement avoir une vitesse de jet suffisamment importante, mais aussi une distribution de gradient de vitesse de jet et une distribution de masse raisonnables. Les paramètres du jet sont étroitement liés à la forme d'onde de détonation de la charge. Par conséquent, lors de la conception de la forme d'onde de la charge creuse, un indice raisonnable de largeur de l'anneau de détonation pour le système de détonation annulaire doit être proposé sur la base des exigences spécifiques des paramètres du jet.