The following is the application of Zongheng Intelligent Control’s data transmission products in successful cases of the Internet of Things.

LoRa remote meter reading system

| LoRa remote meter reading system | Application of ZHC492C in greenhouse monitoring | |

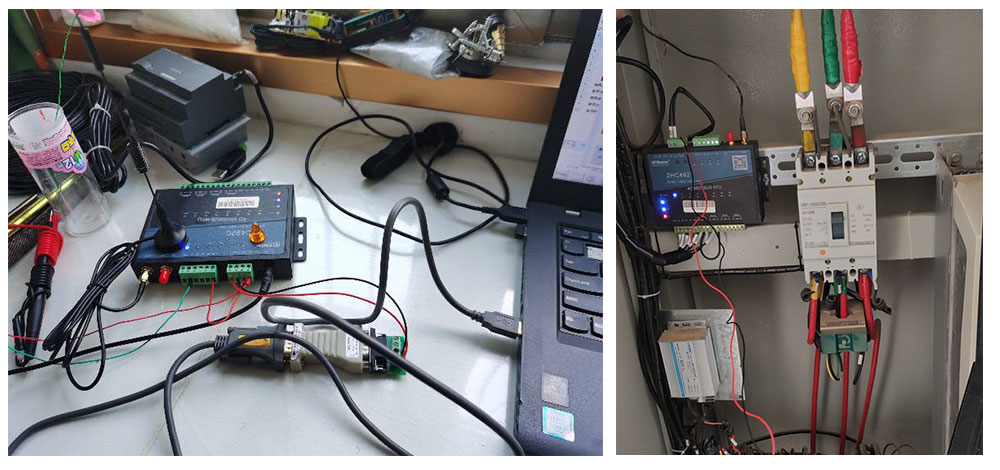

| The remote meter reading system independently developed by Zongheng Intelligent Control can be widely used in residential areas, office buildings and other units and departments that have meter reading needs and real-time meter reading and monitoring and management. The use of this system saves a lot of manpower and material resources for logistics management., achieving a management effect of getting twice the result with half the effort. | In order to fulfill the above requirements, an Internet of Things solution company in Shenzhen developed a remote monitoring system for greenhouses. The main functions of this system include remote monitoring of temperature and humidity environment, soil moisture, automatic (manual control) vents, and water pump switches in the greenhouse. , our company’s product ZHC492C plays a role in it | Zongheng Intelligent Control’s RTU-ZHC492C is mainly used in this system: connected to a three-phase electricity meter, DI monitors whether the switch is on/off (remotely monitors the start/stop status of the water pump), DO remote control output ( remotely controls the start/stop of the water pump), RS485 monitors the electric power. |

|

|

|

| Application of ZHC492C in oil well monitoring | Application of ZHC492C in pipeline monitoring | Application of ZHC4921 in traffic light supervision |

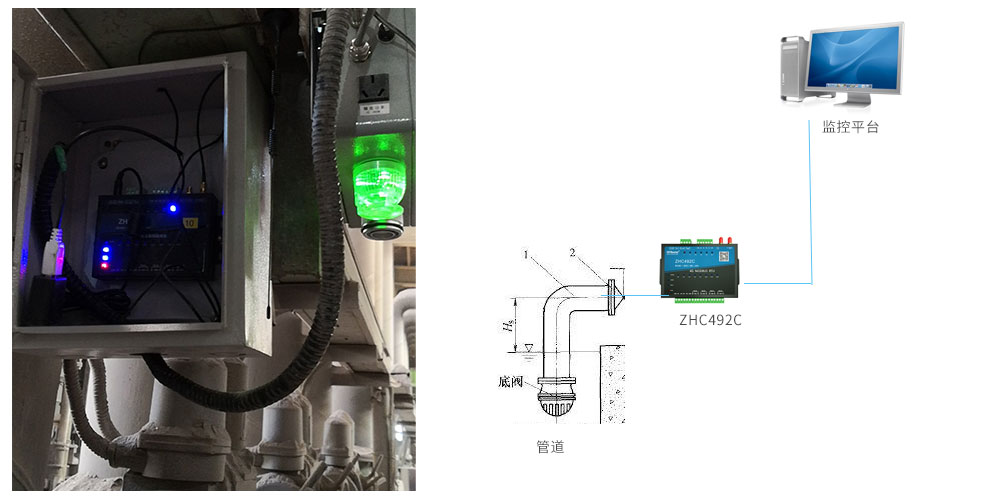

| The intelligent oil well control cabinet is composed of PLC, RTU (ZHC492C), three-item electricity meter, control switch, plug strip, terminal block and control cabinet. RTU (ZHC492C) collects various operating data from PLC and oil well field equipment, pressure sensors, flow meters, temperature sensors and other sensors or secondary instruments and sends them to the monitoring center in real time. Managers can use this system at any time without leaving home. The production status of the oil well is observed, and if an oil well failure or other conditions are discovered, relevant personnel will be immediately arranged to solve the problem. | The implementation principle is to use the AI (analog input) of the analog collector ZHC492C to connect to the sensor placed in the pipeline, and detect the sensor signal through the ZHC492C. After reaching the set value, ZHC492C outputs a switching value to control the alarm device. | Implementation principle: ZHC4921 is connected to the text display circuit board using RS485 to achieve remote transparent transmission. Instructions can be issued from the server to modify the warning sign text. In addition, the lights are connected through DI to monitor whether the issued instructions are executed normally and whether the street lights are normal. |

|

|

|

Keywords in this article: rtu equipment