RS485 principle

This principle, also known as ANSI/TIAEIA-485, TIA-485-A or TIA/EIA-485, is jointly defined by the Electronic Industries Alliance and the Telecommunications Industry Association. Simply put, it is a method used in balanced digital multipoint systems. Standards that define the electrical characteristics of drivers and receivers. In practical applications, communication networks that apply this standard can effectively transmit signals over long distances or in complex environments.

Structurally, the RS485 bus is divided into two lines, A and B. The negative logic of differential signals is applied. The voltage difference between the two lines – (2-6) V is used to represent logic “0”, and the voltage difference between the two lines is used to represent logic “0”. The voltage difference between them is (2-6)V to represent logic “1”. In terms of signal transmission capability, the transmission distance can reach 2km, the transmission rate can reach up to 10Mbps, and the supported nodes are 32. In addition, the special driver can support 256 related nodes.

What is RS485

● RS485 also known as TIA-485(-A) or EIA-485 is a serial communication method for computers and devices similar to RS232.

● RS485 is not only a single device-to-device interface, but also a communication bus used to form a simple network of multiple devices.

● RS485 allows up to 32 multiple devices to communicate half-duplex over a single pair of wires at half distance, while the maximum distance of the ground wire is 1200 meters. (If you wish to extend the length and number of nodes of your network , you can easily do this using repeaters.)

Due to its wide common mode range, RS485 is capable of transmitting data over long cables in noisy environments. Therefore, RS485 is commonly used as a protocol in POS, industrial, telecommunications, especially in noisy environments. RS485 is also common in computers, PLCs , serial servers, microcontrollers, and smart sensors in scientific and technical applications.

How does RS485 work? (Wiring arrangement)

● In RS485, data is transmitted differentially through two twisted wires twisted together (often called “twisted pair cable”). The twisted characteristics make RS485 have high noise immunity and long-distance transmission capabilities.

● As shown in the figure above, the direction of the noise current generated by the environmental magnetic field is opposite to the current in other parts of the cable, making the noise current lower than that of ordinary straight cables.

● In RS485 network, it can be configured in 2 common ways: 2-wire (half-duplex system) or 4-wire configuration (full-duplex system)

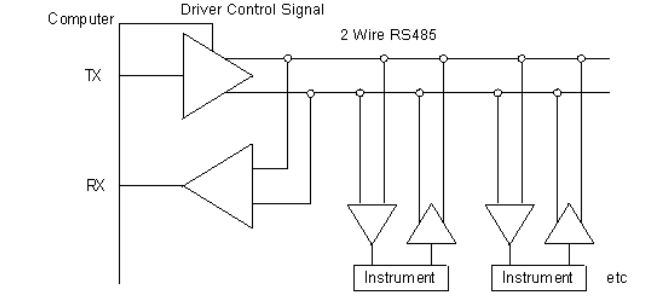

2-wire half-duplex system

● In the RS485 2-wire half-duplex system, data can only be transmitted in one direction at a time. (You can only send or receive data at a time) In this setup, the host TX and RX signals will share a pair of wires, which means you save on installation costs and the nodes can also communicate with each other.

● In this setup, the transmitter and receiver are connected to each node on a twisted pair. However, in this setup it’s limited to half-duplex and there are turnaround delays to be aware of.

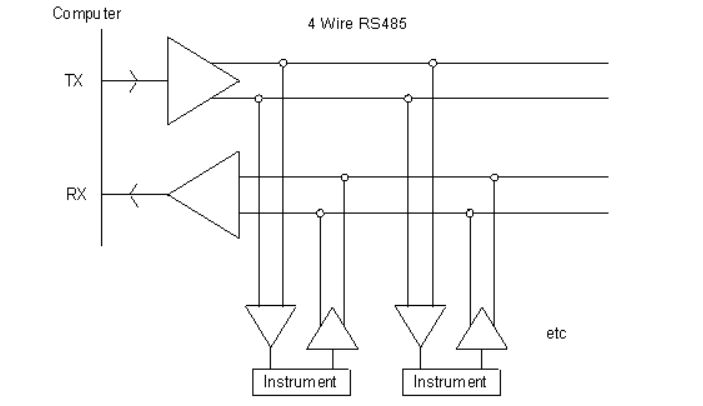

4-wire full-duplex system

● Using this RS485 4-wire full-duplex system, data can be transmitted to and from nodes at the same time. (You can receive and send data at the same time) In this system 2 wires will be used for transmitting and the other 2 wires will be used for receiving.

● In this setup, a master port with a transmitter is connected to each node that receives data on a twisted pair. However, in this full-duplex setup, they are limited to master-slave communication where the nodes cannot communicate with each other.

In the process of enterprise information production, real-time query and traceability of production data are becoming more and more important. However, most enterprises do not realize the function of real-time recording of various production data in the actual production process. traditional compressor oil injection production workshop, because the understanding of information technology is not in-depth and the complex controlled objects are not fully grasped, it is difficult to truly reform the technology, and the manually recorded compression molding machine oil injection production method is still used. 7]. This method of recording data is slow and data updates are not timely, which is not conducive to corporate management management and also leads to a reduction in production efficiency.