In the intelligent management of industrial gas pipeline network, edge computing gateway, as a key hub, is gradually showing its inestimable value. It is not only a bridge for data transmission, but also a frontier for data processing and decision making. Edge computing gateway integrates advanced Internet of Things (IoT) technology and powerful data processing capabilities. It is able to analyze key parameters in the gas pipeline network in real time, including pressure, flow rate, temperature and other key parameters. It realizes accurate monitoring of the status of the pipeline network. It is able to perform preliminary processing and filtering at the source of data generation, effectively reducing the burden on the cloud server. At the same time, it reduces data transmission delays and ensures a quick response in case of emergency. For example, automatically adjust the valve opening to maintain the balance of the network, or timely warning of potential safety hazards.

What are the key benefits of the EG Series Edge Computing Gateways?

-

Rich PLC Protocol Adaptation

IOTRouter‘s EG series gateways support the private protocols of 99% of the major PLC brands on the market, which means that it is easier to communicate with PLC devices of different brands without the need for complex protocol conversions. Massive memory supports a large number of data points, making the system more comfortable in handling large projects. Wide compatibility effectively reduces the need for additional protocol conversion equipment, thus lowering overall project costs.

-

Multi-industry Protocol Adaptation

EG series gateways are compatible with a variety of industry protocols, including BACNet, Modbus RTU, Modbus TCP, DL645, CJ188, IEC104, OPC UA and so on. The support of multiple industry protocols allows system integration to flexibly select matching communication protocols in different application scenarios, improving system compatibility and flexibility. With the built-in support for multiple protocols, system integration can avoid purchasing additional protocol conversion equipment and software licenses.

-

Deeply customizable Node-Red platform

Node-Red is a stream-based development tool. It is mainly used for connecting hardware devices, APIs and online services. With deep customization, IOTRouter provides rich Node-Red controls and self-developed nodes, and continuously enriches the protocols encapsulated into the nodes. This allows system integrators to quickly realize complex logic programming through simple drag-and-drop operations.

-

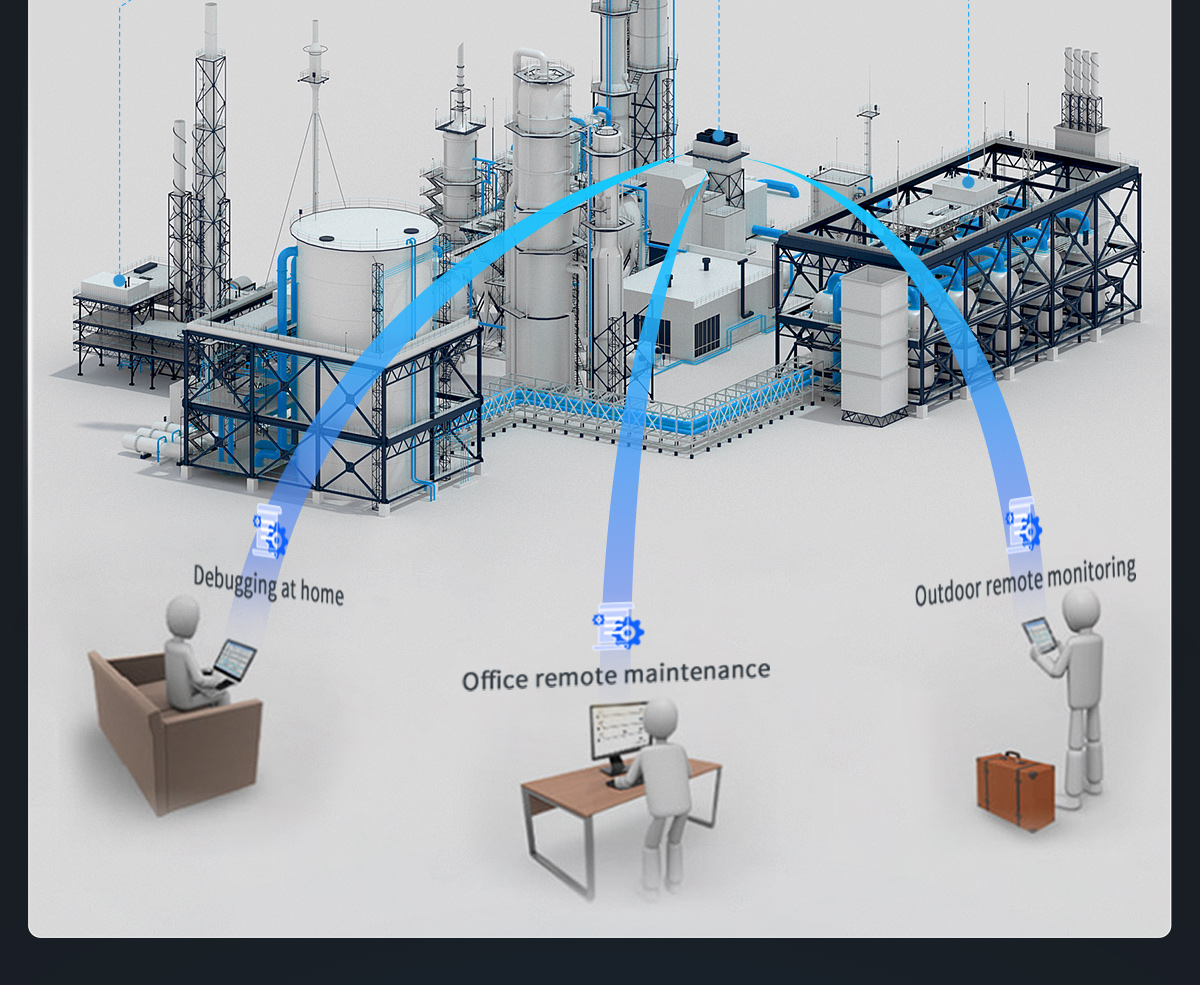

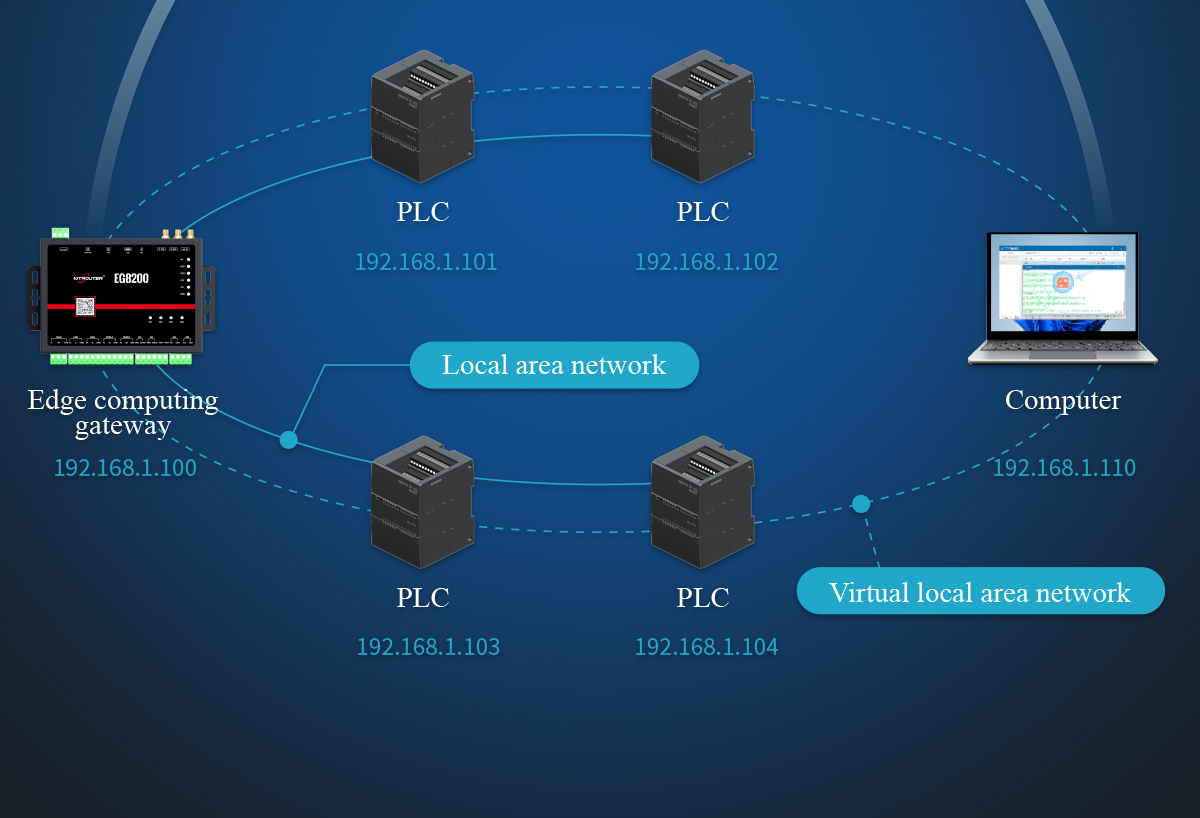

Remote O&M and Management

The remote operation and management function of EG series gateways greatly reduces system maintenance costs. Regardless of where the gateway is installed, the configuration and programming pages of the gateway can be accessed remotely as long as the network is connected properly. This not only reduces the frequency and cost of business trips, but also improves response time, ensuring that the system is back to normal operation in the shortest possible time.

-

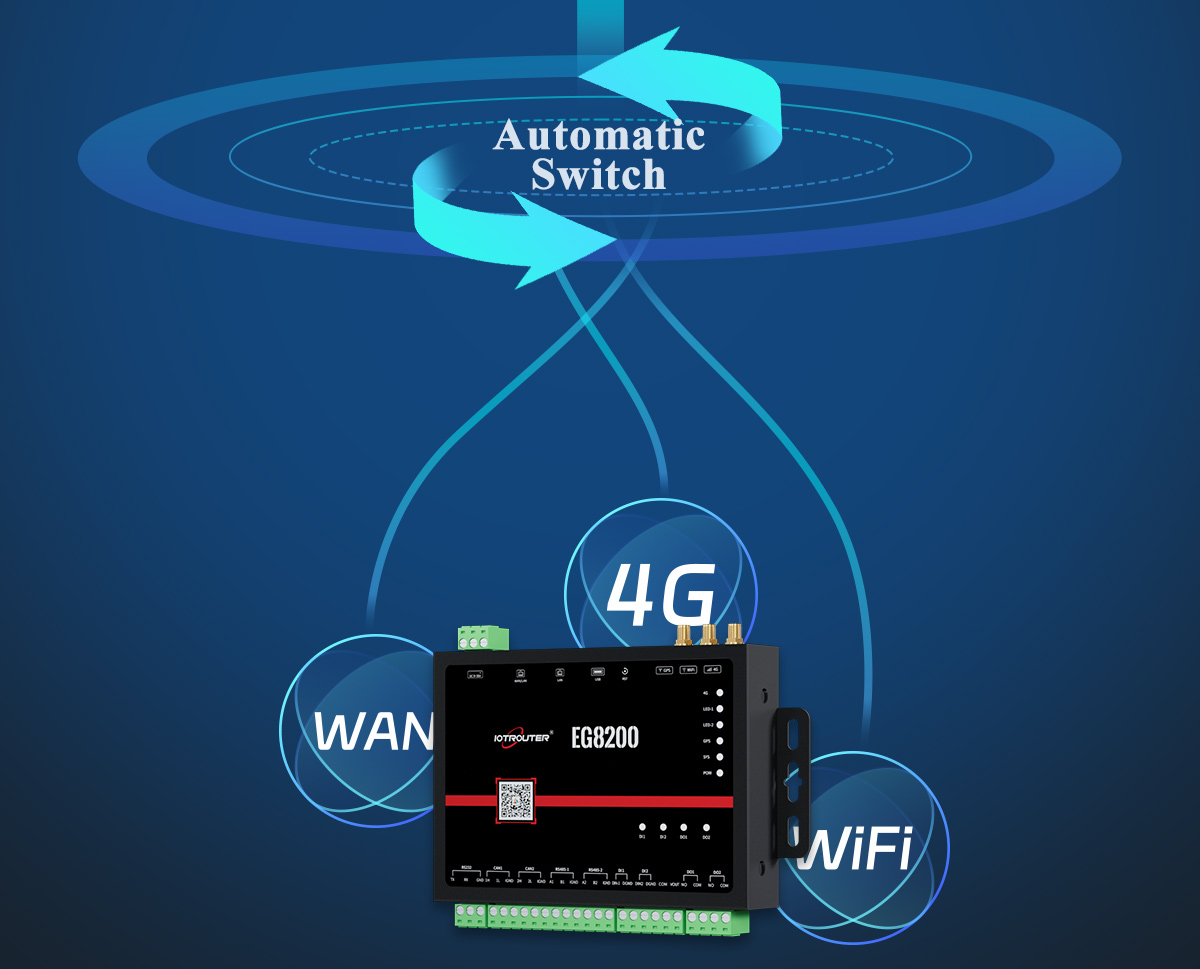

Network self-recovery function

EG series gateways support a variety of network communication methods with automatic switching function. Whether it is wired network, Wi-Fi or mobile network, it can realize seamless switching to ensure high availability and stability of the system. The network self-recovery function reduces the downtime loss caused by network interruption and improves the overall economic efficiency of the system.

The Role of EG Edge Gateway in Intelligent Management of Industrial Gas Pipeline Networks

1.Based on the Node-RED drag-and-drop programming feature of EG8200 series edge computing gateway, secondary development can be carried out very easily and efficiently. In view of the complexity and diversity of different industrial site environments, it can be based on the specific needs of gas pipeline network monitoring. For example, the secondary development of the gateway can be carried out according to the real-time monitoring and abnormal warning of parameters such as air pressure, hydraulic pressure, gas composition, ambient temperature and humidity, vibration and displacement, etc., so as to ensure the accuracy of data collection and the timeliness of processing.

2. A safe and reliable communication network can be constructed through the edge computing gateway. The edge computing gateway needs to establish a stable and secure communication link with the cloud platform and field sensors, actuators and other equipment. Ensure real-time data transmission and synchronization under low-latency and high-bandwidth conditions.

3. Real-time data preprocessing and edge computing analysis. EG Gateway not only collects data in real time, but also performs preliminary data cleaning, compression and initial analysis before the data reaches the cloud, reducing the burden of unnecessary data transmission. At the same time, it can also quickly respond to emergency events, such as leakage alerts. This is conducive to the realization of immediate response and preliminary processing, and improve the overall system emergency response capability.

4. System integration and scalability. It can be seamlessly integrated into the existing industrial gas pipeline network system, and deeply integrated with the existing SCADA (Supervisory Control and Data Acquisition) system, GIS (Geographic Information System), digital twin system, etc., and centrally monitored and dispatched through a unified management platform.

5. Remote operation and maintenance and iterative upgrading. Intelligent industrial gas pipeline network is a continuous process, which requires regular performance evaluation and optimization of the edge computing gateway and its supported systems. Using the remote management function of EG Edge Computing Gateway, system operation and maintenance and upgrading can be realized remotely. It reduces the manual on-site operation process and provides solid technical support for the safe and efficient operation of the industrial gas pipeline network.

6. Safety monitoring and emergency response. Combined with IOTRouter cloud platform, managers can realize centralized monitoring of multiple gas sites, which greatly improves work efficiency and management level. The system carries out 24h real-time online monitoring of equipment and pipeline network status, and can quickly issue alarm messages when abnormalities in the pipeline network are detected. At the same time, it reacts to the control equipment, such as automatic valve closure, automatic pressure relief, automatic firefighting, and notification of maintenance personnel.

This intelligent monitoring system with cloud and edge synergy is gradually building a safety net of industrial gas pipeline network with wide coverage and quick response, which protects the sustainable development of the city and the safe life of the residents.

With the continuous progress of technology and the expansion of application scenarios, EG Edge Computing Gateway will play an even more important role in the future. It opens a new era of intelligent monitoring of industrial gas pipeline network.