In recent years, the development of the Industrial Internet of Things has been in full swing, and various service providers and integrators have sprung up to compete for the market. However, the deployment and implementation of the Industrial Internet of Things in industrial manufacturing is not optimistic. So, what is the difficulty in developing the Industrial Internet of Things? In other words, what capabilities are the core competitiveness of industrial IoT manufacturers?

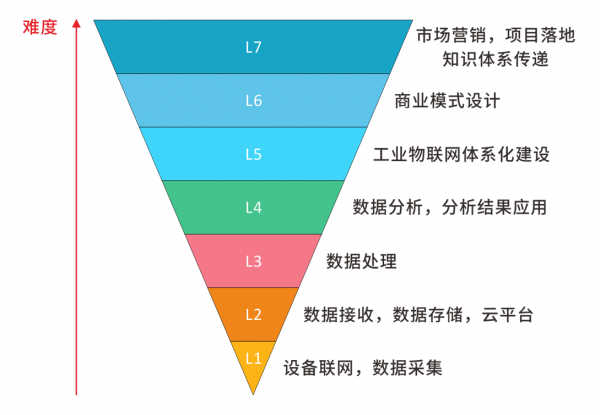

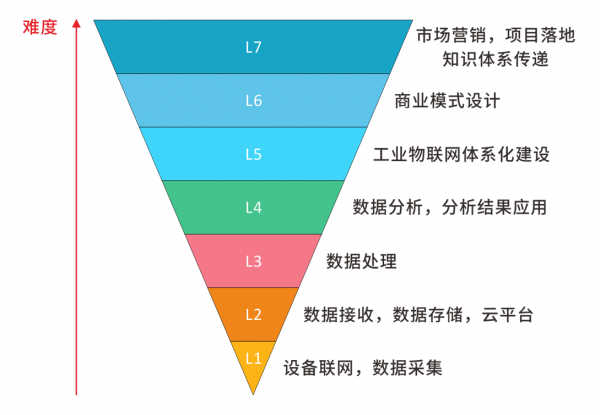

We summarize the difficulty of the Industrial Internet of Things as an inverted triangle.

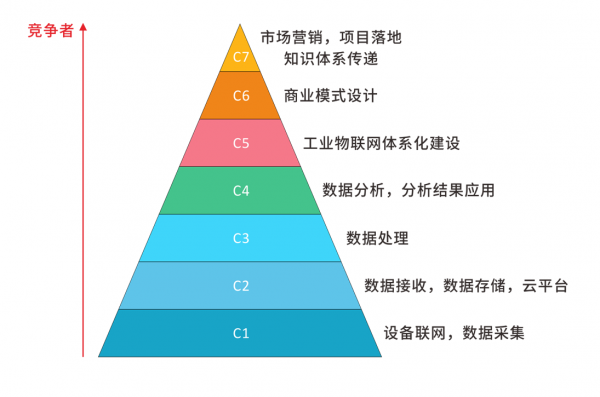

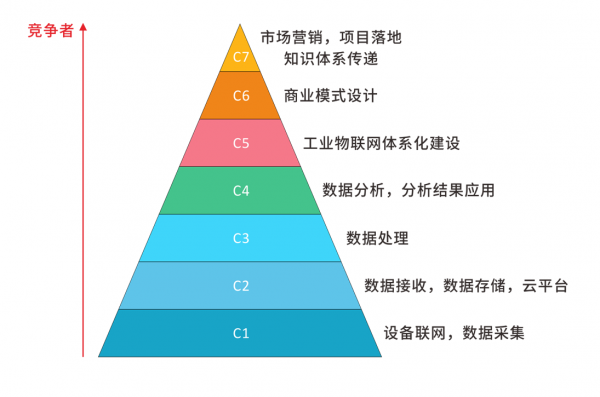

But in the actual market, the competitive state of the Industrial Internet of Things presents a positive triangle.

Why there is such a distribution starts with the technical system of the Industrial Internet of Things.

We divide the technical applications of the Industrial Internet of Things into the following seven layers:

1. Device networking and data collection

With the rapid development of the Industrial Internet of Things, many traditional industrial manufacturing companies have turned their attention to equipment data. To achieve intelligent management and data processing, the first step is to obtain equipment data. So for industrial equipment, is data collection difficult? Equipment manufacturers can’t do it themselves? of course not.

In fact, industrial equipment data collection is to make a hardware terminal and interact with the equipment. As long as you understand the physical interface, interaction protocol, data type, etc. of interaction, this matter is not difficult. But why do equipment manufacturers that have agreements not do data collection themselves, but obtain data through third parties? The difficulty lies not in the data collection itself, because the data of industrial equipment is massive and disorderly.

In addition to data collection, data must be stored, classified, processed, etc. These are all problems that manufacturers need to face and solve. The current situation of China’s manufacturing industry determines that data collection will be a very large market demand, which is spawning a large number of hardware manufacturers, data collection integrators and other service companies that provide basic data interoperability capabilities.

2. Data reception, data storage, cloud platform

Is cloud platform difficult? If equipment manufacturers can’t do it themselves, can’t other software companies do it? Is MQTT the Internet of Things?

Of course it’s negative.

The cloud platform is certainly more difficult than building a data collection terminal, but in the final analysis, the cloud platform is still a solution to terminal-scale access processing capabilities and how to solve large-scale concurrent data storage problems. This is also a purely technical issue, even if Equipment manufacturers can’t do it, but there are still many IoT companies that can do it, such as Alibaba Cloud, Huawei Cloud, Inovance and other companies. What I like is their cloud deployment capabilities and strong strength. They have relatively high guarantees for the data deployed in the cloud. This is something that ordinary companies want to do but are not able to do well.

But having said that, industrial IoT data is a time series data. In most cases, it cannot use the relational database that general software companies are usually familiar with. This is a big threshold for IoT companies, but this threshold is not impossible. Transcendence.

3. Data processing

The so-called data processing means to abstract the data to a high degree and perform necessary processing, so that the data can be stored in a more orderly manner and retrieved efficiently to facilitate subsequent data applications, statistics, analysis and calculations.

In fact, data processing is easily overlooked. Most IoT service providers do not understand what data processing is, let alone how to do data processing well. They can only directly collect and save the data. Application, this brings a series of problems: in the face of a large amount of data, only scattered data can be displayed, but the data correlation relationship cannot be accurately judged, and it cannot assist decision-making, etc.At this level, the strength gap between various IoT companies has been clearly reflected. Companies that can effectively process data can often enter the industry more quickly and provide customers with data value.

4. Data analysis and application of analysis results

Data analysis has two aspects for the industrial Internet of Things:

-A- Analyzing data and forming analysis results is a basic thing that data analysis must do.

-B- Apply analysis results appropriately.

At this stage, industrial IoT companies are generally still in the first phase of “analyzing data”, and very few are starting to do the second phase.

Analysis is a means, not an end. The purpose of analysis is to apply the results of analysis. For the Internet of Things, the purpose of analysis is to achieve safe production, energy saving, emission reduction and improve efficiency. This matter is a real thing. It is difficult for companies that just tout the concept and fail to implement it to implement predictive maintenance. Intelligent IoT has implemented a comprehensive enabling platform for device connection, data processing, and business applications. It can be applied in various industrial scenarios and process various devices and data. The current number of industrial equipment connections has reached 200,000, with a cumulative total of more than 200,000. 10T of industrial operation data.

5. Systematic construction of industrial Internet of Things

The systematic construction of the Industrial Internet of Things is what Industrial Internet of Things solution providers are most proud of. To a certain extent, this is also what distinguishes them from other Internet of Things companies. It is the company’s real soft power in market competition.

6. Business model design

The common industrial IoT needs of equipment manufacturers are to let manufacturers know who their customers are, as well as the location of the equipment, equipment operation methods, equipment operation methods, fault problems, troubleshooting, and understand the problems caused by using the same equipment in different places. Differences, different impacts of different user habits on device operation, etc. There is no doubt that through the Internet of Things, they can change their services from passive to active.

Different companies will make more or less detours when they start out, but they will eventually develop their own business models, and the business model chosen determines how the company will grow over a period of time and what kind of market it will occupy. s position. There is no right or wrong model, but the market will make appropriate choices.

7. Marketing, project implementation, knowledge system transfer

Whether it is the promotion of policies or the red ocean of the market, the marketing of the Industrial Internet of Things has gradually matured, and a large number of implementation projects have been implemented in China. From the demonstration projects of the Industry and Information Technology Commission to the “Cloud Platform” in Guangdong Province, it shows a prosperous future. prosperous scene.