Backward human labor can no longer meet the needs of modern manufacturing. Some developed countries have long begun to invest in automation technology to improve productivity. As a result, in recent decades, with the informatization, digitization, and networking of various products, the production structure of the manufacturing industry itself has become more complex, more sophisticated, and more automated. The information flow within production lines and production equipment, as well as the data in management work, have increased dramatically. Previous automation systems have been unable to meet the higher needs of the manufacturing industry in terms of information processing capabilities, efficiency, and scale. The application of new generation information technology has solved this problem to a certain extent.

Today, a new wave of industrial revolution innovation represented by the Internet is emerging around the world. The core of change is also the application of new generation information technologies such as the Internet. When new forms begin to be injected into the manufacturing field, a new challenge also begins, that is, the challenge of transforming the manufacturing industry from mechanization, electrification, and digitalization to networked, digitalized, and intelligent manufacturing.

(1) Law: Evolution from industrialization to intelligence

The technical characteristics of traditional industrialization are the use of mechanization, electrification and automation to achieve large-scale production and batch sales. In the current complex international competition and China’s environment, in order to enhance the position of China’s manufacturing industry in the global industrial value chain and solve the problem of a large but not strong manufacturing industry, it is necessary to transform from traditional production methods to intelligent production methods.

The law of development of industrialization

The technical characteristics of modern industrialization include, in addition to physical systems (mechanization, electrification, automation), the integration of information systems (computerization, informatization, and networking) to ultimately achieve cyber-physical systems (intelligentization). In the era of “Industry 4.0”, China’s manufacturing industry is developing towards intelligence, and there is huge space and potential. At present, China is in the process of industrialization, and its economic rise must first rely on manufacturing. While the new round of industrial revolution brings many challenges, it will also provide many rare “opportunities” for China’s new round of manufacturing development. Because historical experience shows that every industrial revolution provides “opportunities” for late-developing countries to successfully catch up. Britain, Germany, the United States, Japan, etc. all succeeded by seizing the opportunities of the industrial revolution. As far as the transformation and upgrading of China’s manufacturing industry is concerned, the new round of industrial revolution will also bring “opportunities” for catch-up development.

In the past, China’s manufacturing industry had low technological content and had always been at the low end of the international industrial value chain. The deep integration of industry and informatization has effectively laid a solid foundation for the networked and intelligent development of the manufacturing industry. There is no doubt that in the era of “Industry 4.0”, a new round of industrial revolution will more rapidly drive the deep integration of informatization and informatization. The full integration of information technology into the manufacturing industry will break traditional production processes, production models and management methods. The deep integration of the manufacturing process and the business management system will enable highly flexible configuration of production factors and enable large-scale customized production. As a result, it will effectively promote the traditional manufacturing industry to accelerate the pace of transformation and upgrading.

(2) Laws: Internal and external network collaboration

“Industry 4.0” defines the network collaboration structure between manufacturers, suppliers and even developers. The main purpose is to achieve collaboration between market and R&D, R&D and production, management and communication, thereby forming a complete manufacturing network. , consisting of multiple manufacturing enterprises or participants, which exchange goods and information with each other and jointly execute business processes. The three dimensions of enterprise, value chain and product life cycle run through the manufacturing participants in each value chain. At the top is the management function, and at the bottom is the manufacturing function.

At the same time, the “intelligent production” of “smart factory” focuses on the research of intelligent production systems and processes, as well as the realization of networked distributed production facilities. Its core is the application in the entire industrial production process through cyber-physical systems (CPS). , using the technology, software technology and communication technology of the Internet of Things to strengthen information management and services and improve the controllability of the production process, thereby achieving all-round information coverage in R&D, production, manufacturing processes and industrial control, and comprehensively controlling all kinds of information , ensuring that all production and manufacturing links are in optimal condition. This will guide the manufacturing industry to transform towards intelligence.

1.Internal network collaborative manufacturing

For a manufacturing enterprise, its internal information is centered on manufacturing, including production management, logistics management, quality management, equipment management, personnel and working hours management and other production-related elements. Traditional manufacturing management uses a single workshop/factory as the management unit. The focus of management is production, and the scope of management is within the manufacturing industry.

However, with the advancement of information technology, many manufacturing companies have continuously developed different systems according to the needs of management at different stages of development, and have gradually used them within the company, such as inventory management systems and production management systems. , quality management system, product life cycle management system, supply management system, etc. Different systems implement different functions, and some systems are composed of self-developed or systems from different suppliers. With the development of enterprises, collaboration between different production element management is required to avoid information islands in the manufacturing process. Therefore, there is an increasing demand for interfaces and compatibility between various systems, that is, between various systems Internal collaboration is increasingly important.

In particular, as the requirements for manufacturing agility and lean manufacturing continue to increase, relying on manual import and export of information can no longer meet the needs of manufacturing informatization. This requires network collaboration between different systems to achieve real-time information. Deliver and share.

2.External network collaborative manufacturing

In the future manufacturing industry, each factory will operate independently. Each factory will have an independently operating production management system, or a set of production management systems will be used to manage the operations of all factories. However, with the development of enterprises, enterprises have different production bases and multiple factories. Factories often need to schedule each other and rationally utilize resources such as manpower, equipment, and materials. The flow of information between each factory in the enterprise is getting faster and faster. More and more are coming, and the real-time requirements are getting higher and higher. At the same time, the data volume and execution speed requirements of each factory are also getting higher and higher. This requires network collaboration between different factories to ensure real-time information transmission and sharing.

In the era of globalization and the Internet, collaboration is not only collaboration within an organization, but also often involves collaboration between upstream and downstream organizations in the industry chain. On the one hand, through network collaboration, consumers and manufacturing companies jointly conduct product design and research and development to meet personalized customization needs; on the other hand, through network collaboration, production resources such as raw materials, capital, and equipment are allocated to organize dynamic production and manufacturing. Shorten the product development cycle and meet differentiated market needs.

Horizontal integration in “Industry 4.0” represents the combination of production systems, which is an integration of the entire industry chain. In the past factory production, product or component production was just an independent process with no connection between them and no further logical control. External network collaborative manufacturing allows a factory to produce only part of a product according to its own production capacity and production schedule. External logistics, external factory production, including sales, can connect the entire industry chain. In this way, horizontal industry integration along the value chain is achieved.

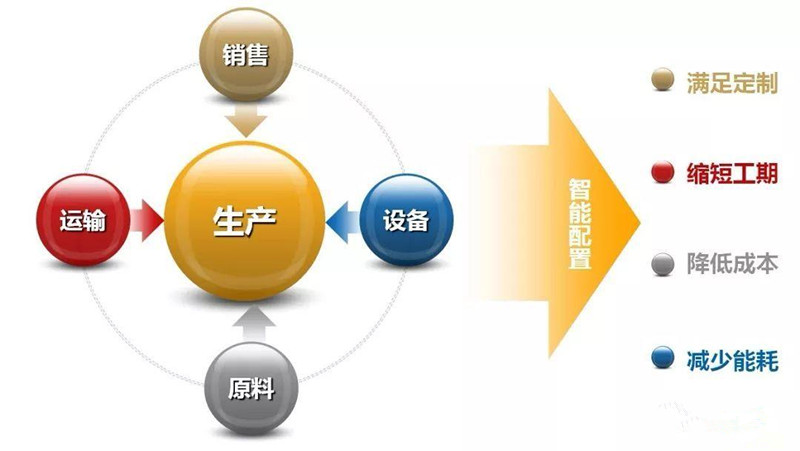

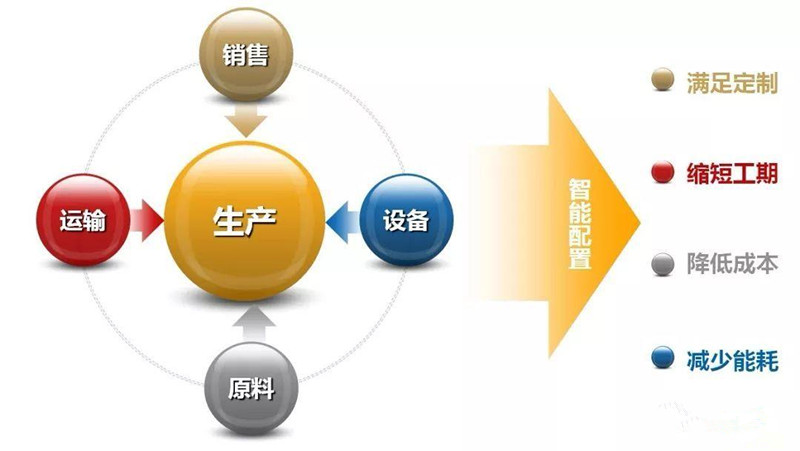

(3) Future manufacturing industry: shorten construction period, reduce costs, improve efficiency, meet customization, and reduce energy consumption

With the popularization of information technology, the Internet, and e-commerce, new requirements for competition in the manufacturing market have changed. On the one hand, manufacturing enterprises are required to continuously obtain information based on the network and respond to market demands in a timely and dynamic manner; on the other hand, manufacturing enterprises are required to dynamically integrate and share various resources and rationally utilize various resources. resource. Interconnected manufacturing can quickly respond to market changes, quickly allocate manufacturing resources through rapid reorganization and dynamic collaboration of manufacturing companies, improve product quality, reduce the time required to put products on the market, and increase market share. At the same time, it can also share infrastructure construction costs, equipment investment costs, etc., and reduce operating risks. The integration of manufacturing resources has broken through the boundaries of enterprises and countries, and is becoming possible to seek resources from around the world based on the Internet. Logistics, capital flow, and information flow will break through regional restrictions and flow dynamically with the support of global economic integration and the Internet. , the world will enter an era of global interconnected manufacturing.

As a future trend, factories will realize the networking of internal and external services through the Internet and the Internet of Things, and develop towards the trend of the Internet Factory. Subsequently, various information from the production workshop is collected and analyzed to provide feedback to consumers. The information collected from the factory can be analyzed as big data to open up more and new business opportunities. How to process the massive data collected from the workshop through hardware will also determine the value of services and solutions to a large extent. In other words, under the Internet manufacturing model, manufacturing companies will no longer centrally control production from top to bottom, and will no longer engage in separate design and R&D links, or separate production and manufacturing links, or separate marketing and service links. Instead, starting from customer needs, to accepting product orders, seeking cooperative production, purchasing raw materials or parts, jointly conducting product design, production and assembly, the entire process is connected through the Internet and communicates in real time to ensure that the final product meets large-scale customers personalized customization needs.

The ubiquitous Internet and convenient logistics systems mean that product research and development, design, production, sales and service processes may not necessarily be completed independently within a company or even a country, but may be decomposed, outsourced, and crowdsourced. Different companies, even countries and regions. In the future, the competitiveness of an enterprise will not depend on how many resources and core technologies it possesses, but on its information data analysis capabilities, resource integration capabilities, and international resource capabilities.

This kind of flexibility in production and manufacturing represents the future development direction of the manufacturing industry. It will enable companies to respond quickly and easily to changes in customer needs, and ensure that their production is competitive and meets the individual needs of large-scale customers. In order to meet the needs of customized customization, the company itself will realize the transformation and upgrading from pure manufacturing to “manufacturing services”.

Boundless, universal, informatized, and fast communication are the characteristics of the Internet. All aspects of the manufacturing industry use Internet technology to visualize the connection between digital information and physical reality, fully integrate production technology and management processes, and realize “Internet” collaborative manufacturing. In this way, it is possible to design and develop, purchase raw materials and components, organize production and manufacturing, and carry out marketing at the same time, thereby reducing operating costs, improving production efficiency, shortening the product production cycle, and reducing energy use.

Advantages of smart manufacturing

Through the Internet and Internet of Things technology, the procurement, production, sales, transportation and other services of manufacturing enterprises and related spare parts supporting enterprises and users are integrated on the network platform, which not only helps to promote the directness and transparency of business processes ization will also improve efficiency and reduce transaction costs.

It can be said that the Internet and the Internet of Things have influenced human society and played a great role in promoting social development. They are the biggest source of the various changes facing society today. In the future, the manufacturing industry will use the Internet and Internet of Things technology to make all links in the manufacturing value chain more closely connected and collaborate efficiently, so that personalized products can be produced in an efficient batch manner, realizing so-called “mass customization.” Intelligent manufacturing in the future manufacturing industry will also bring about major or even revolutionary changes in the product form, design and manufacturing processes, management methods and organizational structures, manufacturing models, and business models of the manufacturing industry, and will lead to major changes in human lifestyles.