With narrowband wireless communication technology, why do IoT terminals still need converged access from gateways? What are the special features of industrial IoT gateways compared to ordinary gateways? With these questions, let us learn about industrial IoT gateways together.

In order to cope with scenarios where a large number of devices are accessed in a small area and devices are accessed in complex environments. The Internet of Things gateway emerged as the times require. The Internet of Things gateway belongs to the network layer in the Internet of Things architecture. Responsible for downlink aggregation and uplink backhaul, in industrial scenarios, IoT-gateways face more challenges.

1. Traditional gateway

First of all, enterprise network products lack industrial design and cannot meet the harsh environmental requirements of industry (traditional network equipment cannot meet the strict industrial-level requirements of the Internet of Things on-site). For example, working temperature requirements, waterproof and dustproof, and strong resistance to electromagnetic interference. Secondly, there are many industrial interface protocols, which impose strict requirements on gateways. Many industrial equipment still need to pass industrial buses such as RS485 and Moabus, or wireless communication methods such as ZigBee and RF. Communication, and the cross-integration of industrial production networks and office networks make them face more complex network security impacts.

Finally, the complexity of IoT network operation and maintenance increases with the increase of terminals. Sites are scattered, deployment workload is heavy, and management is difficult.

2. Industrial Internet of Things Gateway

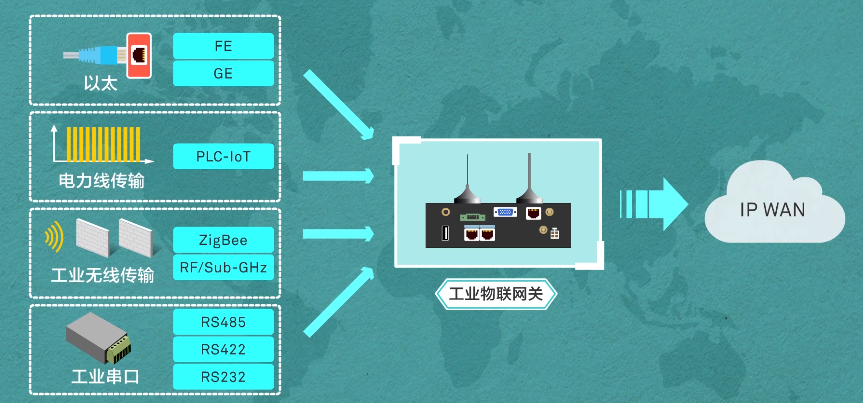

Facing the challenges of the industrial IoT environment, the industriële IoT-gateway is a converged gateway specially designed for networking applications in the industrial field, integrating router, wireless and security.

The industrial IoT-gateway is designed based on industrial-grade standards, supports working in an environment with a temperature of -40°C – 70°C, a humidity of 5%-95%, and is waterproof and dustproof. Fanless cooling meets strong electromagnetic interference and vibration shock standards, and the IoT gateway supports security encryption. Centralize management, provide device attack defense mechanism, resist network attacks, provide software hot and cold patch technology, and achieve smooth online upgrade of device software.

It supports plug-and-play and on-site commissioning-free maintenance methods, and also supports remote centralized management of user-side devices. Greatly reduce users’ maintenance costs and improve maintenance efficiency.

The Industrial Internet of Things can provide a wealth of communication interfaces and protocols, supporting GPRS, 3G, LTE, etc. in the uplink, and Ethernet, ZigBee, RS485, 232, 422, etc. in the downlink.

In addition, the Industrial Internet of Things gateway also supports edge computing. For information about what edge computing is, please refer to the article “The Difference between Edge Computing and Cloud Computing.” After understanding the industrial IoT gateway, let’s learn about some related things, that is, the industrial IoT gateway products. Most industrial IoT gateways currently on the market support the above functions. For example: Chengdu Zongheng Intelligent Control’s wireless gateway product-model is:

ZHL4921. In addition to meeting the functions described above, it also supports GPS positioning functions, local logic operations and other functions. The industrial IoT gateway products are introduced here. If you need to know more about it, please click >> 4G Wireless Gateway.

3. Application of Industrial Internet of Things Gateways

(1) Factory automated production

Using the IoT gateway, all sensor data in an area can be collected, organized, and then sent to the user’s server or computer. Present data in front of users, such as the number of production units detected by sensors, mechanical temperature, and other data, to help administrators better manage. At the same time, threshold values can be reported. If the temperature of a device exceeds 60°C, the data will be reported to the supervision platform. After the administrator sees it, the device will be processed.

(2) Automatic pickup express cabinet

I believe everyone is familiar with this application. There are such express cabinets downstairs in communities, schools and other places. The courier puts the express in the cabinet, and the user can open the corresponding express cabinet by scanning the code. Get your own express delivery. Then the process from scanning the code to opening the express delivery door is the data interaction carried out by the Industrial Internet of Things gateway. The user scans the code, and then the Industrial Internet of Things gateway sends the data to the cloud for identification, and then returns the data to open the corresponding express delivery. Cabinet doors.