Upgrade uw industriële besturingssysteem van traditioneel naar intelligent

With the continuous advancement of science and technology and the development of industrial intelligence, traditional industrial control systems are facing the need for upgrading. In the new wave of industrial revolution, RTU terminals, as a key component, bring unlimited possibilities to industrial production. This article will take you to have an in-depth understanding of the application of RTU terminals in industrial control systems, discuss the importance and advantages of upgrading traditional industrial control systems to intelligence, and provide solutions.

Traditional industrial control systems have many shortcomings in the production process . The production line lacks real-time monitoring, manual operations are too cumbersome, and the operating status of the equipment cannot be grasped in time, resulting in low work efficiency. These problems have brought tremendous pressure to production companies and restricted their development. Upgrading to an intelligent control system can solve these problems and bring more opportunities and development space to the enterprise.

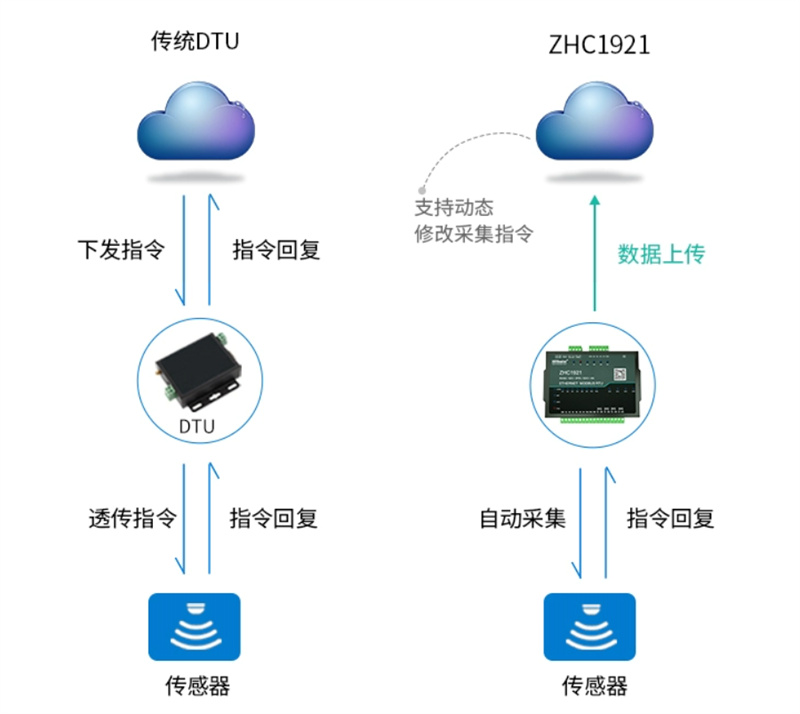

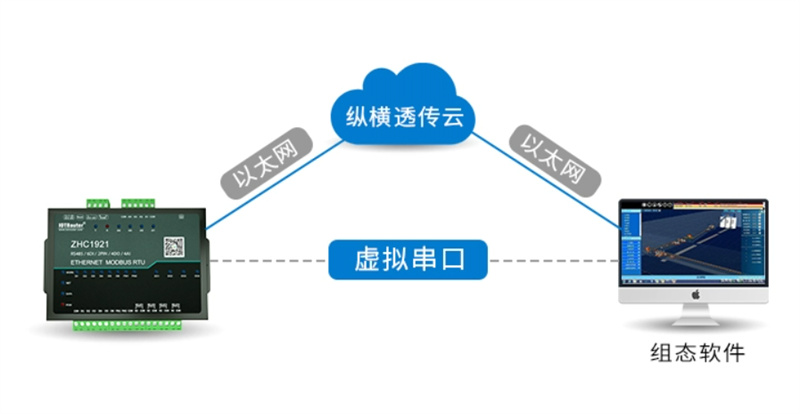

RTU (Remote Terminal Unit) terminal is an important part of industrial control system upgrade. It has functions such as data collection, signal transmission, remote control, etc., and can realize all-round monitoring and control of the production process. Through the RTU terminal, operators can obtain equipment status, parameter indicators and production data in real time to achieve remote monitoring and management, which greatly improves work efficiency and production safety.

The development of artificial intelligence, cloud computing and the Internet of Things provides technical support for the intelligence of industrial control systems. Using cloud platform and Internet of Things technology, RTU terminals can achieve linkage and data interaction with other devices, further improving the level of intelligence in industrial production. For example, through connection with robots and sensors, RTU terminals can efficiently control the operation of the entire production line, realize automated production, and improve production efficiency and product quality.

Intelligent industrial control systems can also provide more data analysis and prediction functions to help enterprises make decisions and plans. Through the collection and analysis of production data, RTU terminals can provide key information such as production efficiency, equipment operating status, and fault warnings, helping companies adjust production schedules in a timely manner, optimize production plans, and reduce production costs.

In short, upgrading traditional industrial control systems to intelligent industrial control systems is the general trend. As a key component, RTU terminals play an important role in improving production efficiency, optimizing production plans and reducing production costs. Its application has brought huge changes and breakthroughs to industrial production. Keep pace with the times, seize the opportunity, comprehensively upgrade your industrial control system, and move towards a new era of smart industry!