Welcome the smart era and understand the key information of RTU programming

In today’s rapidly developing smart era, industrial automation has become the core of many industries. As one of the important technologies for realizing industrial automation, RTU programming has gradually become the focus of attention of professionals in various fields. This article will take you to understand the importance of RTU programming in the smart era, its application in the field of industrial automation, and understand the working principles of real-time control and remote terminal units.

What is RTU programming?

RTU is the abbreviation of remote terminal unit. It is a device that can receive and send data in real time. It is widely used in industrial automation control systems in electric power, oil, natural gas, transportation and other industries. RTU programming is the programming method used when developing related software applications for these RTU devices.

The importance of real-time control

In industrial automation control, real-time control is a crucial link. Real-time control can obtain variable data in time, process and judge it, and then send corresponding instructions for control. RTU programming provides powerful support for real-time control. Through RTU programming, we can flexibly configure RTU equipment to achieve remote monitoring, data collection, fault detection and other functions, thereby improving production efficiency and safety.

How the remote terminal unit works

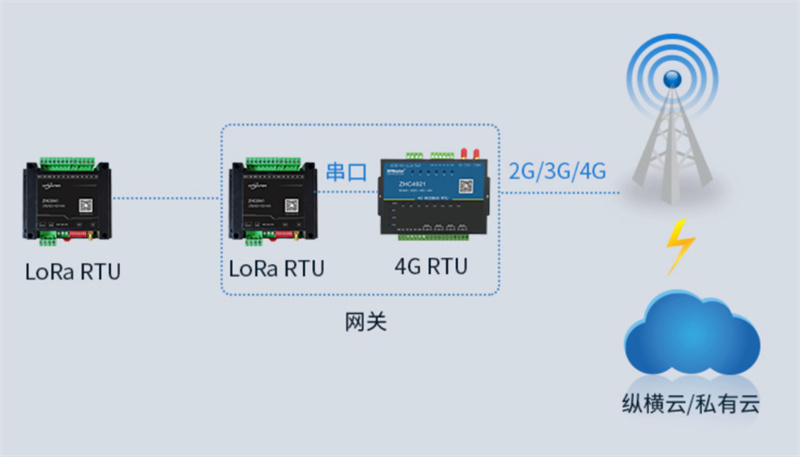

As part of the industrial automation system, RTU equipment mainly realizes data transmission and interaction through communication with the monitoring center or host computer. When the business system or the host computer needs to send instructions to the RTU device, the instructions will be sent to the RTU device through the communication line, and then the RTU device will take corresponding actions according to the instructions. At the same time, the RTU device will also periodically report data and status information to the monitoring center or host computer to ensure real-time and reliability.

Application scenarios of RTU programming

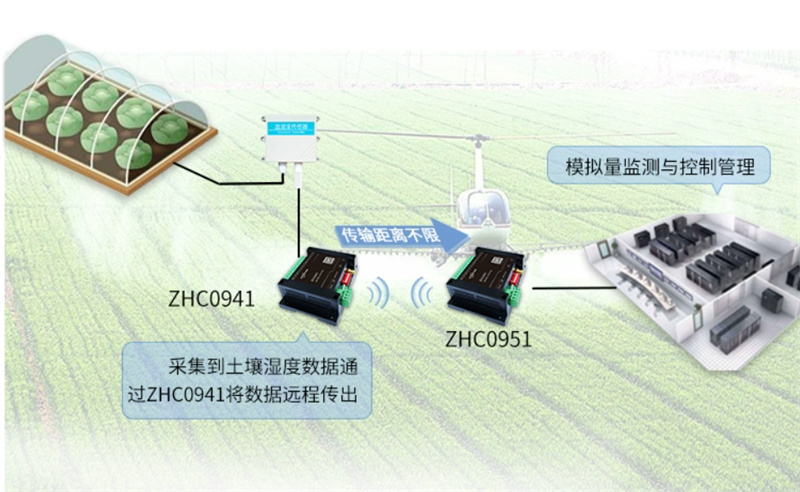

RTU programming is widely used in various industrial automation fields, such as distribution network monitoring and substation monitoring in power systems; pipeline monitoring and offshore oil field monitoring in the oil and gas industry; intelligent traffic signal control in transportation systems, etc. Through RTU programming, these industries can realize remote monitoring, data collection, fault detection and other functions to improve production efficiency and reduce safety accidents.

Samenvatten

With the advent of the smart era, the importance of RTU programming in industrial automation control has become increasingly prominent. The working principle of real-time control and remote terminal units makes RTU programming a key technology for realizing intelligent manufacturing and operations. I hope that through the introduction of this article, you will have a deeper understanding of RTU programming, be able to better apply and promote related technologies in actual work, and meet the challenges of the smart era.