The Internet of Things is developing rapidly, and the Industrial Internet, which is the core of the Internet of Things, will usher in new development opportunities. The proposal and implementation of a series of national strategies such as “German Industry 4.0”, “American Industrial Internet”, and “Made in China 2025” illustrate the Every country is determined to break the boat and hope to create its own world in the industrial field.

According to data, the global IoT device base was 20 billion units in 2017, and is expected to reach 75.4 billion units by 2025, with a compound growth rate of 17%. As the Internet of Things market continues to develop, it is expected that the overall scale of China’s Internet of Things will exceed 1.8 trillion yuan by 2020.

Industrial IoT will drive economic development

As a product of a new type of manufacturing technology, the Industrial Internet is called the new entrance to the Internet of Things era by many people in the industry. Some experts once said that as long as a 1% improvement in efficiency can be achieved, it will produce immeasurable economic value, and 1% has the magic power to leverage a huge economy.

In the global rail freight industry, a 1% improvement in efficiency would mean fuel savings of $27 billion.

In the global medical industry, if medical efficiency increases by 1%, it means saving more than US$63 billion in medical costs.

A 1% improvement in the efficiency of all natural gas-fired power plants worldwide would mean fuel savings worth $66 billion.

General Electric CEO Ismail said the goal of the Industrial Internet is to upgrade those key industrial areas. The Industrial Internet will bring huge changes to the development of the Internet of Things.

It can be seen that using the Industrial Internet of Things to transform traditional industries will bring profound changes to the production, operation and management models of enterprises, improve production and manufacturing efficiency, save energy, promote the transformation of economic development from production-driven to innovation-driven, and promote the transformation of industrial structure. Adjustment.

Industrial Internet of Things market has broad prospects

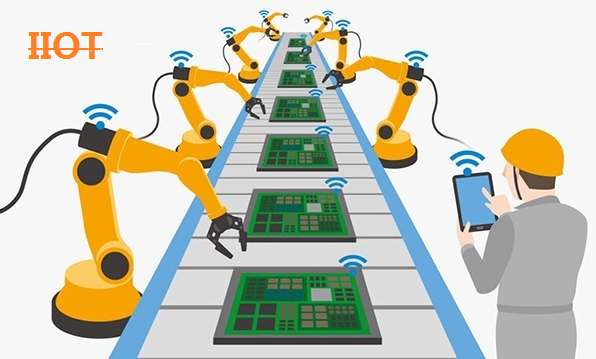

In recent years, various companies have continued to carry out technological innovation to further promote the intelligence of the industrial system. The development of intelligent manufacturing requires the use of industrial Internet of Things technology to push the manufacturing industry into digital manufacturing transformation. This transformation contains a huge market.

According to the GSMA Think Tank, the number of global Industrial Internet of Things (IIoT) connections will reach 13.8 billion by 2025, of which the number of connections in Greater China is approximately 4.1 billion, accounting for approximately one-third of the global market. Meanwhile, according to China’s Ministry of Industry and Information Technology, China’s industrial IoT market revenue is growing at an annual rate of approximately 25% and will reach nearly 300 billion yuan (equivalent to US$47 billion) in 2018. This shows that the Internet of Things and the Industrial Internet of Things are ushering in a period of rapid development.

Alex Sinclair, chief technology officer of GSMA, said that the Internet of Everything is changing the way we live and work. China has invested heavily in the industrial Internet of Things to monitor and simplify industrial production processes, greatly improve production efficiency and reduce production costs. With the strong support of the government, , China will become the global leader in this field.

Industrial production monitoring and optimization of supply chain management system

The development of the Industrial Internet of Things will promote the development of the Industrial Internet. At present, the application of the Industrial Internet of Things is mainly in the optimization of industrial production process management systems, which is mainly divided into the following five points:

1. Enterprise raw material procurement, inventory, and sales: The raw material supply chain management system can apply sensor network technology to improve supply chain efficiency and reduce costs.

2. Production process optimization: Use Internet of Things related technologies to realize production line process detection, real-time parameter collection, production equipment monitoring, and material consumption monitoring, thereby improving product quality and optimizing the production process.

3. Product equipment monitoring: Integrate sensing technology with manufacturing technology to record the usage of product equipment and remotely diagnose faulty equipment.

4. Environmental monitoring: Various pollution sources will be generated during industrial production. Wireless sensing equipment is installed at the enterprise’s sewage outlet to monitor the sewage discharge situation in real time, and the sewage outlet can be closed remotely to prevent sudden environmental pollution accidents.

5. Industrial safety production management: IoT sensors are embedded into mining equipment, oil and gas pipelines, and miner equipment. When workers enter the corresponding places to work, they can monitor the safety status of the workers in real time and sense in real time. If there is an accident, they can be the first to respond. Time to the rescue.

Strengthen the systematization of safety construction and improve safety

With the emergence of every new technology, people are concerned about its safety. Recently, the 4th Internet Security Leadership Summit hosted by Tencent and hosted by the Industrial Internet Industry Alliance was held in Beijing. Among them, Ding Yuzheng, chief information engineer of China State Shipbuilding Corporation, said that in the development process of the Industrial Internet, there are issues such as equipment security and data security. , control security, application security and many other security issues. How to quickly establish a security system for the Industrial Internet has become an urgent issue for the development of the Industrial Internet.

At the meeting, Tencent Security Vice President Fang Bin said, “Industrial Internet security is still a relatively new security field, which is highly complex and cutting-edge. It is difficult for a single enterprise to provide full-link, full-process, and all-weather industrial Internet security capabilities. , openness, sharing, and cooperation have become the consensus in the new situation of the network security space.”

Samenvatten

At present, China is already the largest industrial automation market in the world, with advantages such as large numbers of people, big data, and an increase in dominant companies. However, most of the core technologies of the Industrial Internet of Things are still in foreign hands. How can we accumulate more and learn from advanced foreign technologies? The problems and challenges we face today.