Gateway is a kind of computer system or device that acts as a conversion heavy duty

In the industrial site, PLC assume the role of automation equipment control, affecting the operation of the entire production line, so many companies focus on PLC control management and maintenance, but in the era of epidemic, the disadvantages of sending people on business trips to carry out on-site maintenance is becoming increasingly large, the need to face the possibility of an epidemic at any time, and once it occurs is a week or two of additional spending. For equipment manufacturers, the cost of payment and the risk borne does not match, the efficiency is extremely poor. Therefore, the enterprise for PLC remote maintenance needs more and more strong, the need for a complete set of perfect service, cost-effective solutions.

Industrial Internet of Things System

To achieve remote control of PLC and programme download, in fact, the market has long had a mature and complete solution, only need to choose the gateway industrial to build the right industrial Internet of Things system according to their own needs, you can easily achieve the PLC remote debugging or programme update.

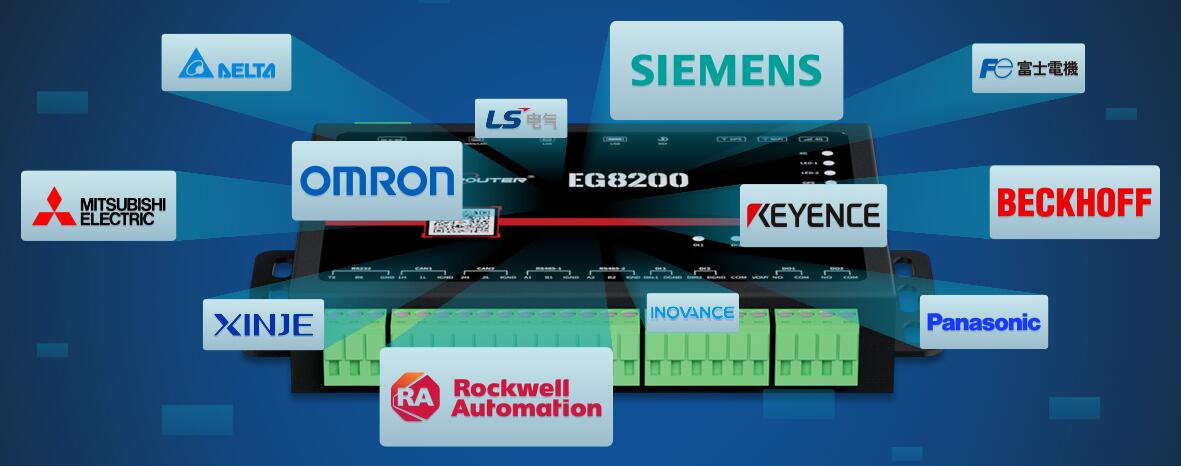

The first step in setting up an industrial IoT system is to choose an industrial gateway with PLC remote configuration function. Industrial gateway provides protocol resolution and device networking, which can resolve PLC protocols such as Xinjie, Siemens, Mitsubishi, Omron, Delta, etc., and can also realise the construction of communication networks such as 5G/4G/WIFI/Ethernet.

The industrial gateway collects relevant data from PLC devices, obtains PLC operation parameters, and monitors device status in real time. And then uploaded to the equipment management cloud platform through the network, it can provide visual data display and convenient interactive operation interface, so that the staff can view the equipment operation status, such as switching, abnormality, and energy consumption at any time in the mobile phone and computer.

Industrial IoT Cloud Platform

The basis of the programme is the industrial gateway, which is responsible for data acquisition and feedback on the status of PLC equipment, while the actual application, remote control, configuration, debugging and program download on PLC needs to be achieved through the industrial IoT cloud platform. The user logs into the cloud platform, realises the modification of relevant parameters, gives commands, and completes the configuration and debugging of PLC. In the event of equipment failure, a remote maintenance channel can be set up to carry out programming such as program downloading and updating to achieve remote maintenance.

Far-reaching Significance of Gateway

The significance of PLC remote maintenance is not only to improve the management efficiency of the equipment, but also to replace the travelling on-site maintenance, which greatly saves costs. The data communication network that collects and uploads data anytime and anywhere can achieve remote monitoring and control, and can also set up safety warnings, provide predictive maintenance support, and provide enterprises with efficient, low-cost, and better maintenance solutions.