Gateway de computação periférica is an emerging technology that pushes computing and data processing capabilities closest to the data source. This article will introduce the application of edge computing gateway in liquid level detection. Liquid level detection plays an important role in many industrial and commercial scenarios, and edge computing gateways can provide real-time, efficient data processing and decision support, making the liquid level detection system more intelligent and reliable. This article will discuss the working principle of the gateway de computação periférica, the needs of the liquid level detection system, and the advantages and application cases of the edge computing gateway in liquid level detection.

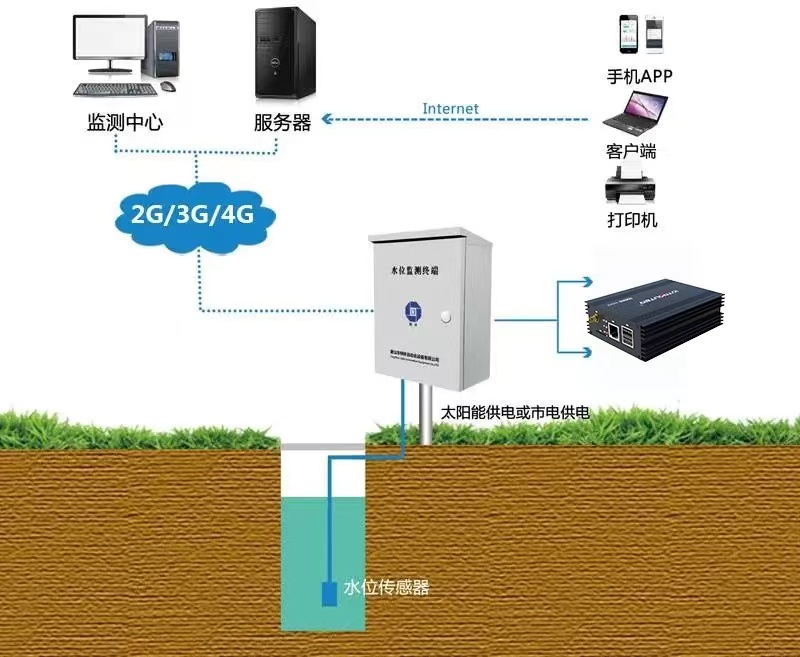

1. Application scheme of edge computing gateway in liquid level detection

Liquid level detection has a wide range of applications in many industries, such as petrochemicals, water treatment, food processing, etc. Traditional liquid level detection systems usually use centralized data processing to transmit sensor data to remote servers for processing and analysis. However, this approach has issues such as data latency, bandwidth pressure, and security. The rise of edge computing gateway technology has brought new solutions to liquid level detection.

2. Working principle of edge computing gateway

An edge computing gateway is a computing device located at the edge of the Internet of Things, which enables fast response and real-time decision-making by placing computing and data processing capabilities closest to the data source. Edge computing gateways can directly connect with sensor devices to collect and process data generated by sensors. At the same time, it can also transmit the processing results to the cloud or other remote servers to achieve comprehensive data analysis and management.

3. Requirements for liquid level detection systems

The liquid level detection system has strict requirements for real-time performance, accuracy and reliability. Rapid collection and real-time analysis of liquid level data are the key to timely warning and decision-making. Edge computing gateways can meet these needs by moving data processing and analysis functions closer to the data source, reducing data transmission delays and providing higher data processing efficiency.

4. Advantages of edge computing gateway in liquid level detection

Edge computing gateway has the following advantages in liquid level detection:

4.1 Real-time:

The edge computing gateway can quickly respond to sensor data, analyze liquid level changes in real time, and issue early warning signals in a timely manner.

4.2 Efficiency:

The edge computing gateway has local data processing and analysis capabilities, which can realize real-time processing and filtering of data and reduce unnecessary data transmission. This can reduce the pressure on network bandwidth and reduce dependence on remote servers, improving overall system efficiency.

4.3 Reliability:

The edge computing gateway can continue to operate in the event of network disconnection or network failure, ensuring the continuity and stability of the liquid level detection system. It can cache the processing results and transmit them when the network recovers, avoiding data loss and delay.

4.4 Security:

Because edge computing gateways push data processing and analysis locally, the risks of data transmission over the network can be reduced. Sensitive data can be encrypted and securely stored within edge devices, improving the security and privacy protection of liquid level detection systems.

5. Application cases of edge computing gateway in liquid level detection

5.1 Industrial production:

In industries such as petrochemicals and water treatment, edge computing gateways can monitor liquid level changes in real time and issue alarms when thresholds are exceeded. This helps prevent accidents such as spills and leaks, and ensures the safety and stability of industrial production.

5.2 Food processing:

During food processing, edge computing gateways can monitor the liquid levels of food raw materials and finished products to ensure precise control and quality management of the production process. It can detect liquid level abnormalities in time and take measures to avoid product contamination or waste.

5.3 Water resources management:

Edge computing gateways can be used for liquid level monitoring and early warning systems in water sources such as reservoirs and rivers. By monitoring water level changes in real time, water resources can be better managed and allocated to avoid problems such as floods and water supply shortages.

Resumir

Edge computing gateways have important application potential in liquid level detection . It achieves improvements in real-time, efficiency, reliability and security by moving data processing and analysis capabilities closer to the data source. Edge computing gateways are widely used in industrial production, food processing, water resources management and other fields, providing strong support for the intelligence and optimization of liquid level detection systems.