In industrial environments, PLC is increasingly used in production processes, automation control and other scenarios. However, under the premise that production life and automation requirements are constantly changing, PLC programming is not static. Workers often need to change PLC programming. Optimizing the production process and automated control procedures requires moving a computer in a small space to update the operating procedures, which is a large cost in terms of time and manpower.

With the rapid development of IoT devices, more and more gateways are entering different industrial scenarios and playing different roles. In order to solve the pain points of PLC on-site upgrade and reduce time and labor costs, Chengdu Zongheng Intelligent Control Technology Co., Ltd. took a year to develop an edge computing gateway: EG8000, which perfectly solves this problem.

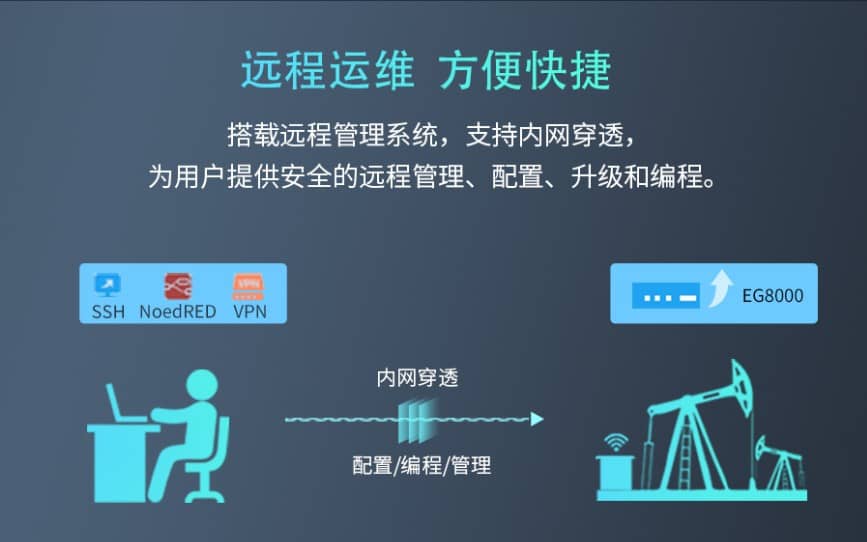

Based on the RTU and DTU of the old era, this edge computing gateway has been updated with secondary development and integrated PLC’s private protocols, including Siemens s7 protocol and PLC general protocol OPC ua protocol, for data interaction and monitoring with PLC. At the same time, we can use the open VPN function of the gateway to virtualize an IP and remotely communicate with the PLC through the PLC programming software to achieve the purpose of remotely uploading and downloading PLC programs. The operation is simple and the performance is powerful.

If a gateway can only remotely upload and download PLC programs, its functions are monotonous and not very practical, because there are always additional needs in production and life; a gateway that can only remotely upload and download programs is definitely unsatisfactory, because it cannot solve the problems of production and life. Most of the questions. First of all, the gateway has 2 RS485 serial ports and 1 RS232 serial port, which is suitable for data collection in most industrial environments; secondly, the gateway is based on the Linux system, integrating node red tools, visual programming, and streamlining requirements through pulling The nodes form a process to achieve the required functions. What is more valuable is that the gateway has a js secondary development function. When local computing, packaging, and logic are required for data, this function can solve these fragmented needs. The fully customized mode satisfies Diverse industrial environments; finally, under wireless or special needs, the gateway will always be required to store data locally. Of course, this EG8000 gateway must have this function. It supports writing files and time series databases, and locally stores 2 G or above, can be expanded.

China has a vast land and rich resources, and the largest population in the world. If you want to be rich and powerful, you cannot do without a strong industrial environment and production environment. The diversified industrial environment and production environment bring a variety of industrial protocols. The EG8000 gateway currently supports a full range of networks. protocol, and the data protocol supports most industrial protocols, but is still being improved. The advancement of industrial automation and production and life is inseparable from the coordinated operations of communication gateways and edge computing gateways. There is a long way to go to become an industrial power and achieve full automation. Chengdu Zongheng Intelligent Control Technology Co., Ltd. is committed to the R&D and production of Internet of Things communication terminals. In order to solve and develop common scenarios such as industry, production and life, and construction, it constantly updates product functions and capabilities.

Other keywords: edge computing gateway