2) Fire and gas monitoring system: The monitoring of fire is mainly completed through the bundle tube monitoring system. The smoke and temperature sensors caused by tape, electrical appliances and fires cannot be installed.

Bit. The number of underground monitoring points for gas, CO, temperature, wind speed and other sensors of the safety monitoring system needs to be increased.

3) Roof pressure monitoring system: The pressure data transmitted to the well has not been developed and applied, and there is no alarm and pre-warning function; the working surface does not realize the support tilt alarm function; there are no pressure monitoring points within the advance support range of the upper and lower tunnels on the 1376 working surface.

4) Each detection and monitoring system is independent of each other, and there is no unified data processing and management platform.

1.3 Key issues to be solved in the transformation

1) The identification and early warning of major hazards in coal mines involve many disciplines such as geology, hydrology, mining, ventilation, detection, monitoring, mathematics, computer communications and networks, and only comprehensive analysis of multi-disciplinary information can achieve hazard identification. source purpose. Therefore, a unified data processing platform and data warehouse must be established. In addition, since a large amount of spatial information and monitoring and control equipment are involved, a unified geographic information system platform and configuration software must be adopted or developed.

2) It is necessary to establish an early warning indicator system for known danger sources (such as old lanes, old kilns, water inrush faults, security coal pillars, collapse pillars, etc.); for real-time identification and analysis of danger sources (such as roof collapse, gas and water inrush) etc.) need to achieve rapid transmission and feedback of information.

3) Develop a professional decision support model library to realize detection and early warning of dangerous sources such as water, fire, gas, and roofs. Based on the comprehensive analysis of the basic data and time series data of major hazards, the method of combining qualitative analysis and quantitative analysis was used to classify major hazards in coal mines, and an evaluation model and index system library for major hazards in coal mines were established.

4) Realize data sharing between the underground gas monitoring system and the ventilation numerical processing system, develop an online digital ventilation network dynamic management visualization system, and realize real-time calculation and abnormal diagnosis of the wind network.

5) Realize online detection of parameters related to major hazard sources. ① Improve the comprehensive hydrological monitoring system. In addition to online monitoring of surface water temperature, water pressure and other parameters, an online monitoring system based on underground industrial Ethernet is also implemented to monitor changes in water temperature, water level, flow rate, water quality and other parameters in real time. ② Add smoke and temperature sensors to conduct online fire prevention detection of the underground main transportation belt; the bundle tube monitoring system monitors the O, N, CO, CH, CO, CH, CH, CH, and other gas contents at the underground monitoring location Achieving 24-hour continuous monitoring, through the measurement and analysis of natural fire marker gases, timely prediction and prediction of temperature changes at the ignition point, and judgment of the oxidation of the coal surface, providing a scientific basis for the prevention and control of natural fires in coal mines and mine gas accidents. The safety monitoring system continuously monitors CH, CO, temperature, wind speed, smoke and other information in the underground environment through underground sensors, and displays it in real time through ground GIS software to achieve dynamic prediction and early warning. Analyze the mechanisms of hazard sources such as gas and fire, quantify some indicator systems, and establish corresponding models to use expert systems for analysis and early warning. ③The main contents of the mine pressure observation work include: observation of the initial support force and working resistance of the working face bracket and advance support; observation of the displacement and velocity of the roof of the tunnel and mining tunnel; observation of the overload stress of the anchor rod or anchor cable; surrounding rock Or observation of internal stress in coal mass.Although the initial supporting force and working resistance data of Qianjiaying Mine’s 1376 working face bracket and advanced support have been transmitted

to the ground, but does not provide a shared interface, so it is necessary to standardize the data interface and create a unified data platform. ④The data collection system related to water, fire, gas and roof pressure is based on industrial Ethernet and realizes the interconnection of the mine and group company networks. ⑤ Based on GIS and other technologies, develop an integrated data storage and processing platform for identification, prediction and early warning of major coal mine hazards; combine with new communication technology, research modern enterprise management systems and management models that are compatible with informatization to give full play to information technology Fast, real-time, and intuitive. ⑥For practical applications in coal mines, develop a special configuration software platform for coal mines to realize communication configuration, database configuration, table configuration, curve configuration, animated graphics configuration, true three-dimensional graphics configuration, underground personnel positioning configuration, and storage group configuration, data processing configuration, voice configuration, image configuration, and early warning plan configuration.

2 Implementation of data transmission system between group company and Qianjiaying Mine

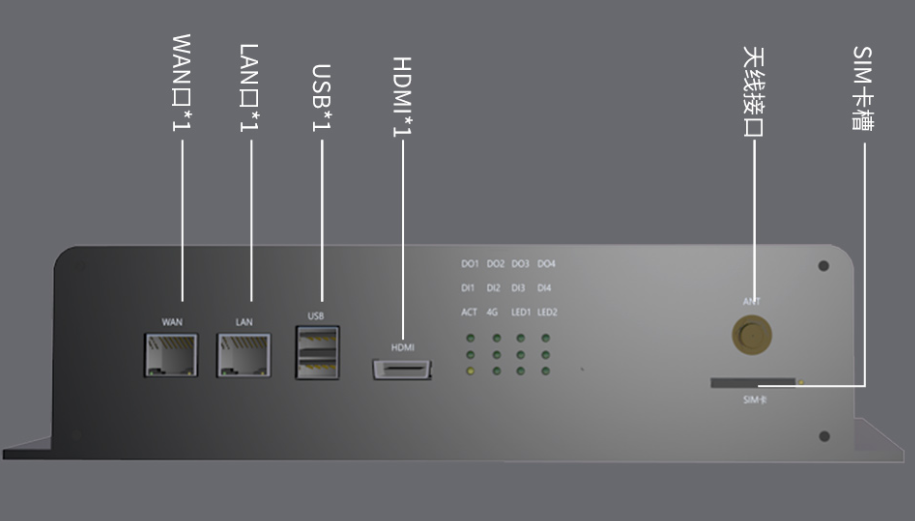

The information control center of Kailuan (Group) Company is the center where the group’s internal network and the uploaded information required by each mine are collected. It is equipped with hosts and servers to form an internal LAN. The group LAN and each mine subnet have different IP addresses, and can be linked to each mine subnet through the group company’s internal network. The transmission system adopts Gigabit optical fiber Ethernet ring network. According to the actual physical distribution characteristics of each system in the mine, a dual-ring dual-network (surface ring network and underground ring network) dual-redundant and tree-branched network structure that meets the characteristics of the mine is constructed to achieve Multi-network integration channels are shared to establish high-speed and stable comprehensive automation network channels. Through the Gigabit optical fiber ring network, it provides nearby access network interfaces for various subsystems and equipment involved in the system, provides an unimpeded high-speed transmission channel for remote centralized monitoring and control of the system, and forms branches of the network through branch trees to provide system The expansion provides unlimited space.

2.1 Transmission system functional characteristics

Based on 10OOM industrial Ethernet, it realizes the simultaneous transmission of voice, data, video and other signals in one core optical fiber, realizing three-in-one data communication; it adopts network redundancy technology to adapt to the harsh environment of coal mines; with the network platform as the core , integrates real-time data streams according to unified data standards, has a unified data warehouse and integrated programming configuration, and has strong security mechanisms such as identity authentication, authorization, and encryption.

2.2 Platform network structure diagram

Since there is a long distance between Kailuan Group Company and Qianjiaying Mine, and the group company has a large amount of data queries on the mine, this puts forward higher requirements on the quality and bandwidth of network communication between the group company and the branch mines. Require. At present, a dedicated communication link has been laid between the group company and Qianjiaying Mine. This project does not require the construction of a separate network and the addition of data exchange equipment.

2.3 Integration of various monitoring and control networks and Ethernet

Since the beam tube monitoring system and the safety monitoring and control system are already mature systems in mines, the software platform only needs to read data from the databases of the two systems through interfaces on the ground network. The roof pressure monitoring system and hydrological monitoring system upload sub-station monitoring data through the entire network platform through the data conversion interface, achieving real-time online monitoring. Even the data collected manually can be uploaded and analyzed in time through the interface device to minimize the delay as much as possible. The system is shown in Figure 1.

When α is set to 3, the highest positioning accuracy is achieved, and the average positioning error is 3.1283m. The improved weighted centroid positioning algorithm with virtual node correction achieves the highest positioning accuracy when α is set to 2, and the average positioning error is 2.8114m. Based on the above three situations, it can be seen that when the width of the tunnel changes, in order to obtain the highest positioning accuracy, the value of α changes, and this value can be obtained through experiments. By comparing the two algorithms, it can be seen that when the two algorithms reach the highest positioning accuracy, under three different lane widths, the improved weighted centroid positioning algorithm based on virtual node correction reduces the average positioning error by 13.86% compared with the modified weighted centroid positioning algorithm. 13.18%, 10.13%.