After experiencing three major industrial revolutions, the world is on the cusp of the fourth industrial revolution. With the wave of the fourth industrial revolution, the new generation of information technology will have a profound impact on traditional manufacturing. From “Industry 4.0” advocated by Germany to smart manufacturing and the latest industrial Internet of Things, the transformation and upgrading of the manufacturing industry has become an irreversible trend.

Application of Internet of Things in Industry

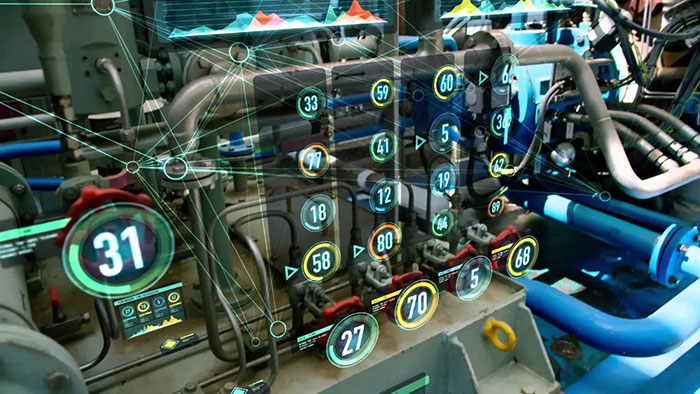

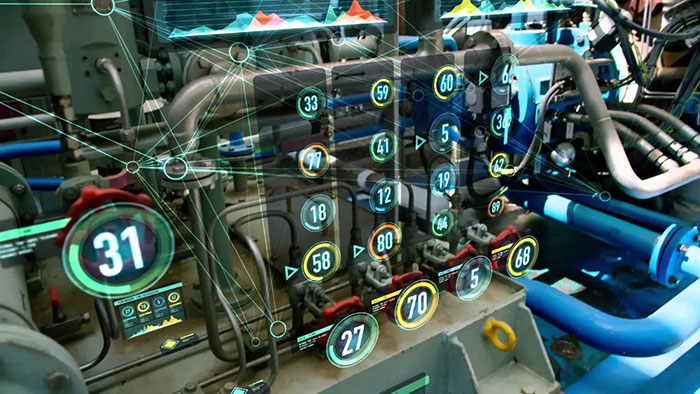

The Internet of Things emphasizes the connection of all hardware equipment in life and production; the Industrial Internet of Things refers to the connection of production equipment and products in an industrial environment. The Industrial Internet of Things turns every link and equipment in the production process into a data terminal, collects underlying basic data in an all-round way, and conducts deeper data analysis and mining to improve efficiency and optimize operations.

Unlike the application of IoT in consumer industries, the foundation of IoT in industrial fields has existed for decades. Systems such as process control and automation systems, industrial Ethernet connectivity, and wireless LANs have been running in factories for years, connecting programmable logic controllers, wireless sensors, and RFID tags. But in the traditional industrial automation environment, everything only happens in the factory’s own system and is never connected to the outside world.

The Industrial Internet of Things is a platform for diversified integration and mutual exploration between different elements. It can connect various sensors, controllers, CNC machine tools and other production equipment at the production site. With the development of the Industrial Internet of Things, the smart devices connected to the Industrial Internet of Things will become increasingly diversified, and the massive data generated by network interconnection can be transported to any place in the world.

By applying sensing technology, communication technology, transmission technology, data processing technology, and control technology to all stages of production, ingredients, and warehousing, we can realize digitalization, intelligence, and networking of production and control, improve manufacturing efficiency, and improve product quality. Reduce product costs and resource consumption, and ultimately upgrade traditional industries to a new stage of intelligence. At the same time, through the cloud service platform, it targets industrial customers and integrates cloud computing and big data capabilities to help traditional industrial enterprises transform. As the amount of data increases, edge computing, which tends to process data at the data source, does not need to transmit data to the cloud and is more suitable for real-time and intelligent processing of data. Therefore, it is safer, faster, and easier to manage in the foreseeable future. will be used more effectively.

Characteristics of Industrial Internet of Things

By 2020, the business of the Internet of Things in the world will be 30 times that of the Internet of People. The industrial field is currently the application field with the most IoT projects. The manufacturing industry accounts for about 15% to 25% of the Internet of Things applications. The important position of the manufacturing industry in the Internet of Things is obvious.

● Scope of data collection: The Industrial Internet of Things uses RFID, sensors, QR codes and other means to obtain information and data at all stages of products from production to sales to end-user use. However, data collection in traditional industrial automation is often limited to the production quality inspection stage.

●Internet transmission: The Industrial Internet of Things uses a combination of dedicated networks and the Internet to accurately transmit object information in real time. It is more dependent on the network and emphasizes data interaction.

● Intelligent processing: The Industrial Internet of Things comprehensively uses intelligent computing technologies such as cloud computing, cloud storage, fuzzy identification, and neural networks to analyze and process massive data and information, and combines it with big data technology to deeply explore the value of data.

● Self-organization and self-maintenance: Each node of the Industrial Internet of Things provides the entire system with information or decision-making data obtained by its own processing. When a node fails or the data changes, the entire system will automatically make corresponding adjustments based on logical relationships.

Future Trends of Industrial Internet of Things

In the future, the focus of enterprise industrial IoT applications will shift from equipment and assets to products and customers. The main ways for industrial companies to achieve business growth through the Internet of Things include new products and services and closer customer relationships. In order to develop more attractive products or improve existing customer relationships, companies will need a large amount of product and customer-related information to support them.

The improvement of data capabilities will make the improvement of data analysis and computing capabilities a priority for investment. The overall breakthrough of the Internet of Things not only relies on hardware capabilities and business model innovation, but algorithms and data are also indispensable. Chinese manufacturing companies have accumulated a large amount of experience data based on application research and development for many years. If this data is extracted and modeled to form practical expert algorithms, the data will become a gold mine with good profitability.

Advances in technology have greatly increased the potential strength of IoT solutions in the industrial field. IoT solutions will improve the operational efficiency of industrial enterprises, increase their revenue sources and stimulate innovation. The Internet of Things has also proven that it can help companies create more sustainable value, such as transforming past one-time transactions into long-term customer relationships. Despite the problems of connectivity and security, we can still expect that the Internet of Things will hit all major industries in the industrial field.