1. Enterprise Background And Pain Point Analysis

With the arrival of the era of Industry 4.0, intelligence and information technology have become the road to enterprise transformation and upgrading. However, many traditional enterprises still face many pain points in industrial equipment data collection. These enterprises often have a large number of production equipment, but the lack of effective data collection means, resulting in equipment operating status, production data and other information can not be timely and accurate access, which in turn affects the enterprise’s production efficiency and decision-making level.

Specifically, these enterprises are facing the following major problems:

Backward Means Of Data Collection: Traditional data collection methods often rely on manual operation, inefficient and error-prone, unable to meet the needs of modern production.

Serious Data Silo Phenomenon: Data between different devices can not be effectively shared, resulting in the phenomenon of information silos, affecting the enterprise’s overall data analysis capabilities.

Insufficient Data Processing Ability: The enterprise lacks professional data processing and analysis team, which is unable to conduct in-depth mining and analysis of the collected data, and it is difficult to find the value behind the data.

2. The Solution And Implementation Effect

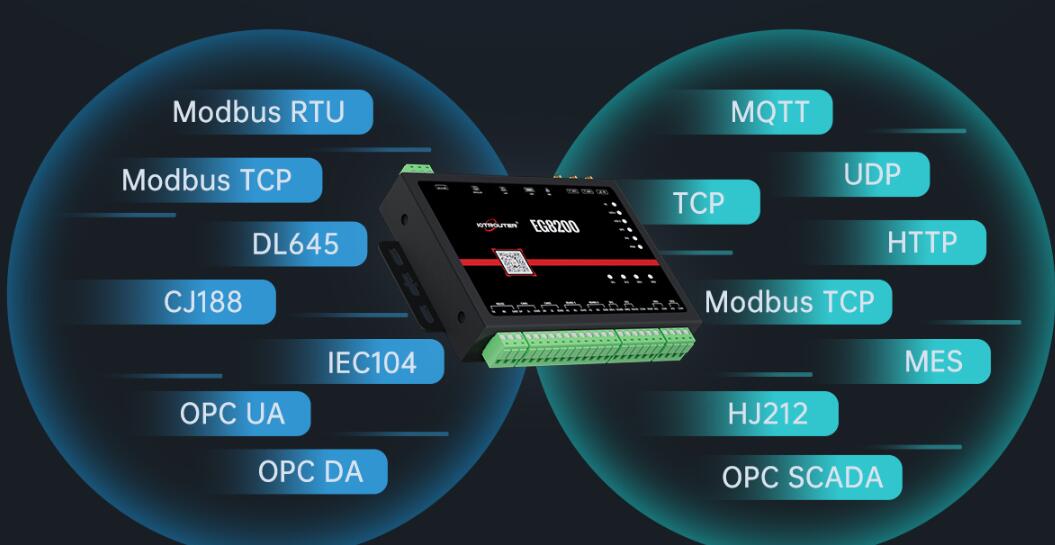

To address the above problems, we propose an industrial equipment data collection solution based on IoT technology. By deploying sensors, IOTROUTER Шлюз для пограничных вычислений and other devices, the solution achieves real-time monitoring and data collection and processing of the operating status of production equipment, and analyses the data through the Digital Network Nebula platform.

After the implementation of the programme, the enterprise has achieved significant results:

The Efficiency Of Data Collection Has Been Greatly Improved: Through the automated collection method, manual intervention has been reduced, and the accuracy and efficiency of data collection have been improved.

Data Sharing And Integration: Data interoperability between different devices is realised, information silos are broken, and a more comprehensive view of data is provided for the enterprise.

Data Value Mining: Using the powerful computing capability of the Digital Network Nebula platform, the collected data are deeply mined and analysed to help enterprises find problems in the production process, optimize the production process and improve production efficiency.

3. Summary and Prospect

Through the implementation of industrial equipment data collection solutions based on Internet of Things technology, the enterprise has successfully broken through the limitations of traditional data collection methods to achieve real-time, accurate data collection and efficient processing. This not only improves the productivity of the enterprise, but also provides powerful data support for enterprise decision-making.

Looking ahead, with the continuous progress of technology and the expansion of application scenarios, industrial equipment data acquisition will play an important role in more fields. We will continue to deepen our research and optimise our solutions to provide more efficient and smarter data collection services to help enterprises achieve digital transformation and intelligent upgrading.