What does rtu device mean?

A remote terminal unit (RTU) is a microprocessor-based electronic device used in industrial control systems (ICS) to connect various hardware to a distributed control system (DCS) or supervisory control and data acquisition (SCADA). RTU is also known as remote telemetry unit or remote control unit.

The RTU passes sensor data from the input stream in the control loop to the output stream and then forwards it to centralized control in the ICS. RTU automatically negotiates connections to local or remote controls.

The RTU monitors analog and digital field data. RTUs acquire data from sensors monitoring target industrial process variables and then forward that data to centralized monitoring and control. The RTU’s hardware includes the setup software needed to connect the data output streams, communication protocols, and built-in troubleshooting. These devices are usually powered by AC power with a DC converter and sometimes by battery backup.

Wikipedia:-RTU

A Remote Terminal Unit (RTU) is a microprocessor-controlled electronic device that controls connected objects by transmitting telemetry data to and from the main monitoring system. [1] Other terms that may be used for RTU are remote telemetry unit and remote control unit.

The RTU monitors digital and analog parameters in the field and transmits the data to the SCADA master station. It runs setup software to connect data input streams to data output streams, define communication protocols, and troubleshoot field installation issues.

An RTU may consist of a complex circuit card consisting of the various parts required to perform a customized function, or it may consist of many circuit cards, including a CPU or processing with a communications interface, and one or more of the following : (AI) analog input, (DI) digital (status) input, (DO/CO) digital (or control relay) output, or (AO) analog output card.

The RTU might even be a small process control unit with a small database for PID, alarms, filtering, trending and other functions, supplemented by some BASIC (programming language) tasks. Modern RTUs typically support the IEC 61131-3 programming standard for programmable logic controllers. Since RTUs may often be deployed in pipeline and grid protection systems, or in other hard-to-reach or extreme environments (such as in Biosphere 2 projects), they are required to operate under harsh conditions and implement energy-saving measures (such as shutting down when not in use) IO module). For example, it communicates via RS485 or wireless communication links in a multipoint configuration. In this type of configuration, it is a remote unit used to collect data and perform simple control tasks. It has no moving parts and uses very low power and is usually solar powered.

Where is rtu applied?

Petrochemical (petroleum) and refineries

Nuclear Power Plant

сельское хозяйство

QC

chemical plant

Sewage treatment plant

food processing

Car manufacturer

Pharmaceutical manufacturing

water treatment plant

RTU device

|

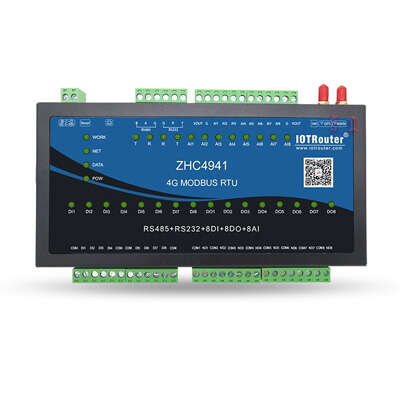

ZHC4941 is an industrial-grade 4G RTU that provides 8 DI, 8 DO, 8 AI and 1 RS485/232 interfaces. It supports local logic processing operations, automatic collection and active reporting, Modbus RTU/TCP adaptation, and automatic calibration thresholds. Reporting, configuration software docking, dry and wet node IO detection and other special functions support one-to-one and many-to-one networks |

|

ZHC495C is a network IO product that supports 8 channels of dry (wet) node detection, 8 channels of relay (COM, NO) output, and 1 channel of RS485 transparent transmission. It is compatible with Modbus RTU/TCP protocol. With “remote control” as the core function and high ease of use, users can easily and quickly integrate it into their own systems to achieve remote and local control based on LTE and RS485. |

|

ZHC492A is a network IO product that supports 4-channel dry (wet) node detection, 4-channel relay (COM, NO, NC) output, 4-channel analog quantity (current 4~20mA) detection, and 1-channel serial port transparent transmission. It supports docking Alibaba Cloud IoT platform. With “remote control” as the core function and high ease of use, users can easily and quickly integrate it into their own systems to achieve remote and local control based on LTE and RS485. |

The composition of RTU

An RTU consists of several major components. These include: (1) communications interface, (2) microprocessor, (3) non-volatile memory, (4) environmental sensors, (5) override sensors, and (6) used to communicate with the device or interface bus board. This bus is often called a fieldbus or device bus.

Several standards (or protocols) are used to communicate with the RTU. These include general and proprietary protocols. Perhaps the most widely used general protocol is MODBUS. Others include ODBC, OPC and ISO Controller Area Network (ISO 11898). Examples of proprietary protocols include Weatherford’s Baker 8800 protocol and Allen-Bradley’s Data Highway.

RTUs can have many different types of interface boards. These interface boards can be digital or analog and can provide input only, output only, or a combination of both. These main types of interface boards are often abbreviated as AI, AO (Analog Output), DI (Digital Input) or DO. Interface boards connect to physical objects using wires.

RTU related articles:

Шлюз Zongheng Intelligent Control RTU помогает зимним Олимпийским играм в Пекине

What is the difference between RTU, PLC and DCS?

Беспроводной модуль RTU_поддерживает протокол mqtt

Разница между Modbus TCP и Modbus RTU

rtu control system application

RTU application cases:

Application of RTU-ZHC492C in greenhouse monitoring

Application of RTU-ZHC492C in water pump monitoring

Application of RTU-ZHC492C in smart farm supervision in Thailand

Application of 4G RTU-ZHC492C in oil well monitoring

Application of 4G RTU-ZHC4921 in traffic light supervision